How Data-Rich Workplaces Can Improve Worker Safety, Health, and Experience

A productive approach to emerging workplace technologies would focus on two overarching goals: 1) accelerating development, testing, and adoption, and 2) supporting positive uses of the technology while mitigating negative ones.

Contents

Policymakers Are Misreading the Workplace Technology Moment 3

Workplace Technology Innovation Surges While U.S. Adoption Stagnates 5

What Data Workplace Technologies Actually Collect 19

No One-Size-Fits-All Approach to the Workplace. 20

Reframing the Workplace Technology Debate. 20

Design Flaws in Emerging Workplace Technologies 21

A Smarter Regulatory Lens For Workplace Technology 22

The Current Standards Regime is Unfit For the Modern Workplace. 24

Introduction

Imagine a futuristic hospital. An automated system alerts emergency room staff that an incoming patient has a blood-borne pathogen based on their electronic health record, allowing the hospital to prepare additional safety precautions. An electronic system tracks staff as they enter patients’ rooms, reminding them if they forgot to wash their hands as they move between patients. And wearable health monitors tracking heart rate data and other indicators of stress and fatigue recommend when staff should take breaks to ensure that they stay healthy and provide optimal care.[1]

This vision of a technology-forward workplace in which an invisible layer of algorithms supports and protects workers is not science fiction. It is increasingly realizable with today’s technology, building on decades of developments miniaturizing computers, sensors, and batteries, as well as improvements in networks and machine learning technologies.[2] The same is true for other industries and workplaces, from capital- and labor- intensive factories to white-collar offices. Technology—including data, hardware, and software—that can enhance workplace safety, accessibility, productivity, and convenience is quickly maturing.

However, U.S. policy at the federal and state levels is woefully behind and not advancing at a fast enough pace to realize this potential. Current policy discussions about the future of work are inadequately narrow to keep up with the rate of advancement in emergent workplace technology. These discussions are also counterproductive, fixated almost exclusively around critics’ claims that data-collecting workplace technology is a means to one end: worker surveillance. What this problematic narrative does is both slow down potential upsides from adopting these technologies and fuel unproductive regulation. A productive policy approach to the advent of emergent workplace technology would focus on two overarching goals: 1) accelerating development, testing, and adoption of innovative workplace technology and 2) supporting positive uses of the technology while mitigating negative ones.

This report explores the future of workplace technology and the benefits such technology can bring to both employers and employees. It also considers the role of other stakeholders, such as technologists and policymakers, in this conversation. Without dismissing drawbacks that come with a more automated, data-driven workplace environment, this report instead explores options that policymakers have to incentivize worker benefits in the limited window before wider adoption of these technologies takes place. It also looks at the current state of federal and state policy governing the usage of workplace technology and concludes with practical policy recommendations that aim to spur discussion and new approaches to this topic.

Specifically, policymakers should recognize the potential of data-rich workplaces by aiming to simultaneously boost workplace technology research and development (R&D) and increase adoption with outlined employer responsibilities and worker protection measures. To do so, the Center for Data Innovation recommends the following:

▪ Establish a federal framework clarifying lawful uses of workplace data and distinguishing protective from invasive technologies.

▪ Boost workplace technology R&D through dedicated federal funding and pilot programs.

▪ Leverage federal procurement to accelerate adoption of safety- and productivity-enhancing technologies.

▪ Modernize workplace safety standards with flexible, outcome-based rules and voluntary tech-enhanced programs.

▪ Direct the Government Accountability Office (GAO) to evaluate positive impacts of workplace technologies alongside risks.

▪ Reshape public narratives on surveillance and create a nonregulatory oversight body for workplace technology.

▪ Expand data collection on adoption, use, and workforce impacts of next-generation workplace technologies.

▪ Target state and local policies to high-risk contexts, incentivizing protective and beneficial technology adoption.

Policymakers Are Misreading the Workplace Technology Moment

Globally, researchers are rapidly inventing and developing technologies that can help white- and blue-collar workplaces become digitized, automated, and data-driven. Yet, the United States is squandering this transformation. As shown in figure 1 through figure 4, corporate adoption of next-generation workplace technology is low across the United States, the global rate of invention and research toward workplace technologies is growing quickly, especially for software applications, and U.S. organizations that have adopted workplace technology are mostly limited to large manufacturing companies.

In response to this technological reality, policymakers’ one-dimensional and skeptical approach has been counterproductive, and will not benefit workers or workplace technology’s potential. Efforts to label and regulate these technologies as only surveillance tools will conversely threaten to keep the private sector’s adoption rate of the technologies low and cost workers unrealized and transformative health, safety, and work experience benefits they might otherwise be able to gain from further adoption.

Ideally, the conversation in policymaking circles should move past a framing of surveillance and toward a new era of technology-enhanced workplaces. While surveillance should not be discounted as a potential harm that increased workplace technology adoption poses, exclusively focusing on surveillance would be akin to banning automobiles in the 1920s because they could cause accidents, or rejecting the Internet in the 1990s because it could enable fraud. Like artificial intelligence’s (AI’s) wide applicability to society and business, workplace technology is also an umbrella of different technologies that presents multifaceted use cases, enormous benefits, and risk.

Federal Narrative Incorrectly Frames Workplace Technology as Surveillance

A 2024 GAO report epitomizes how this misguided narrative treats all workplace technology as inherently suspect and would prevent the hospital scenario described earlier from becoming reality.[3]

Based on public responses submitted to the Office of Science and Technology Policy (OSTP) on employers’ usage of automated systems, the GAO report paints a one-sided picture of workplace technology’s impact on U.S. workers.[4] While GAO briefly acknowledged that four commenters—including a union—stated that “employers use digital surveillance tools to prevent or reduce illness,” the report buries these benefits under alarmist framing.[5] GAO decisively titled the accompanying blog “‘Why do I feel like somebody’s watching me?’ Workplace Surveillance Can Impact More Than Just Productivity,” which reinforces a fear-based lens.[6]

OSTP’s intent in its study was “to better understand automated surveillance and management of workers … to ensure that these systems do not undermine workers’ rights, opportunities, access, health, or safety.”[7] That is an important goal and, indeed, this study’s data, if publicly released, could be a valuable resource for researchers examining the adoption, ongoing implementation, benefits, and challenges of workplace technology.

OSTP’s study should have been accompanied—if not preceded—by additional surveys that explored potential benefits of workplace technology. Unfortunately, the framing of both the OSTP study and GAO’s report reveals a predetermined conclusion that workplace technology is inherently harmful, which ultimately foreclosed a more constructive policy conversation.

The Vocabulary Problem

A central issue in this debate is linguistic. In its report, GAO categorized a wide range of technologies—from cameras and microphones to wearable sensors and braking systems—all as “surveillance.”[8]

Almost all technologies collect data, but data collection alone does not equal surveillance. If an employer provides safety equipment with sensors, those sensors collect data on environmental conditions and usage patterns. The data enables safety benefits, but it does not transform the equipment into a surveillance device, nor does it preclude employers from misusing that data for inappropriate monitoring.

A thermographic camera might detect early signs of fire risk. A wearable might track worker fatigue to reduce injury. These are examples of electronic monitoring that supports worker safety. Surveillance, by contrast, carries a connotation of suspicion or distrust, implying employer observation aimed at detecting employee wrongdoing or enforcing discipline. For example, an employer using cameras to secure its facility is fundamentally different from one using cameras to monitor what employees eat during their lunch breaks. The issue is not what technology they use, but how they use it and why. Employers can cross a line into surveillance when monitoring becomes disproportionate or punitive, such as tracking workers off-duty.

Policymakers should adopt language that reflects this distinction. Otherwise, they will overregulate technologies that help workers and underregulate those that harm them. More useful vocabulary would distinguish between data collection, electronic monitoring, and surveillance based on purpose, transparency, and context.

Three Policy Principles for Workplace Technology

Effective workplace technology policy requires departing from traditional regulatory approaches in three ways:

1. Policymakers should balance innovation for employers and innovation for workers, as unlike consumer technology, workplace technology sits at the intersection of employer efficiency and worker welfare. Traditional policy has often treated worker protection and business needs as oppositional.[9] Policy should instead explicitly support innovations that benefit both employers and workers, rather than framing them as zero-sum trade-offs.

2. Policymakers should regulate usage, not technology. The same sensor that informs a worker when they have walked into a dangerous construction zone becomes problematic if an employer uses it to track employees’ off-duty activities. By contrast, reasonable on-site monitoring—such as ensuring that all staff are accounted for during a fire evacuation—serves a legitimate safety function. Policy should focus on context, purpose, and proportionality rather than banning entire categories of technology.

3. Policymakers should plan for integration stages. Most workplace technology fails not because of the technology itself, but because of poor implementation. Policy should address the full value chain and life cycle—design standards, deployment requirements, and ongoing governance—not just data collection rules.

Workplace Technology Innovation Surges While U.S. Adoption Stagnates

The United States faces a paradox: While workplace technology innovation accelerates globally, U.S. companies are barely adopting these tools. This gap between technological possibility and workplace reality represents a missed opportunity for worker safety and economic competitiveness.

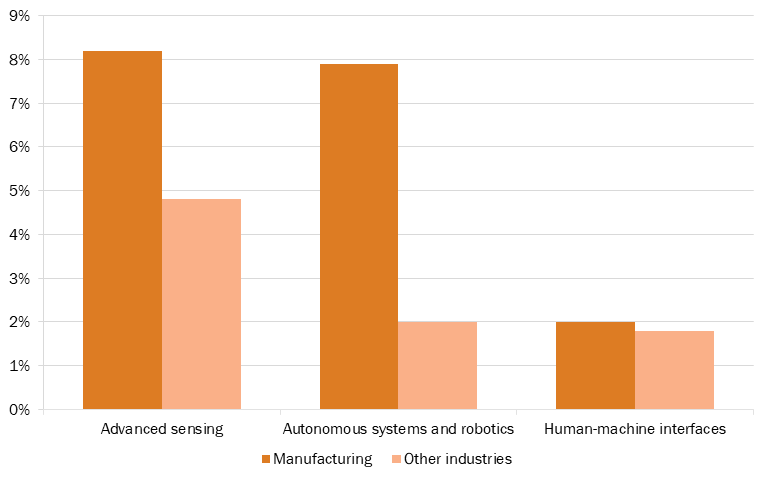

Data from the U.S. 2022 Annual Business Survey shows that as of 2021, only approximately 4 percent of surveyed companies had adopted advanced workplace technologies such as human-machine interfaces, autonomous systems, and advanced sensing capabilities, as seen in figure 1. [10]

Figure 1: Technology adoption by workplace type, 2021[11]

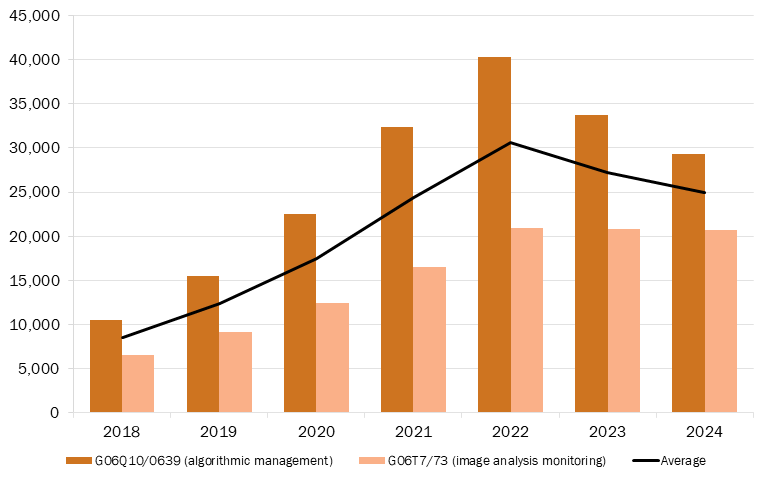

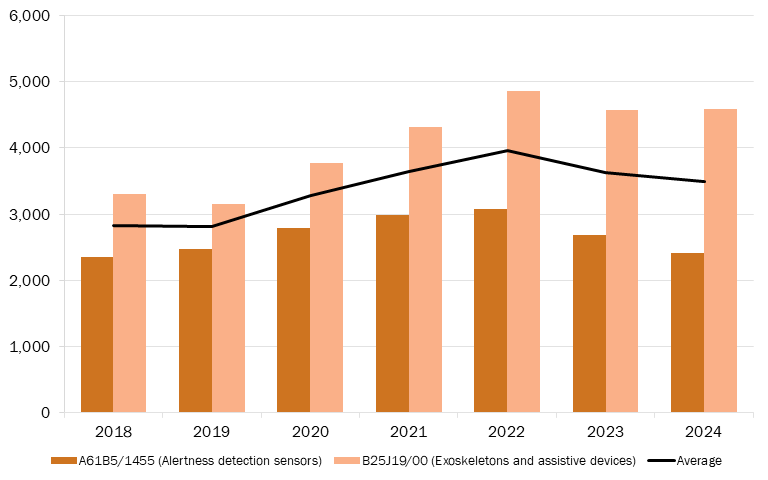

Meanwhile, as shown in figure 2 and figure 3, patent filings for these same technologies, including both the software that underpins them and developments toward their hardware, have grown steadily, indicating robust innovation that is not reaching U.S. workplaces. The drop in filings in recent years likely reflects reporting and publication lags rather than an actual slowdown.

Figure 2: Patent publications of workplace technology software research[12]

Figure 3: Patent publications of workplace technology hardware research, 2018–2024[13]

Large Manufacturers Lead, All Other Companies Lag Behind

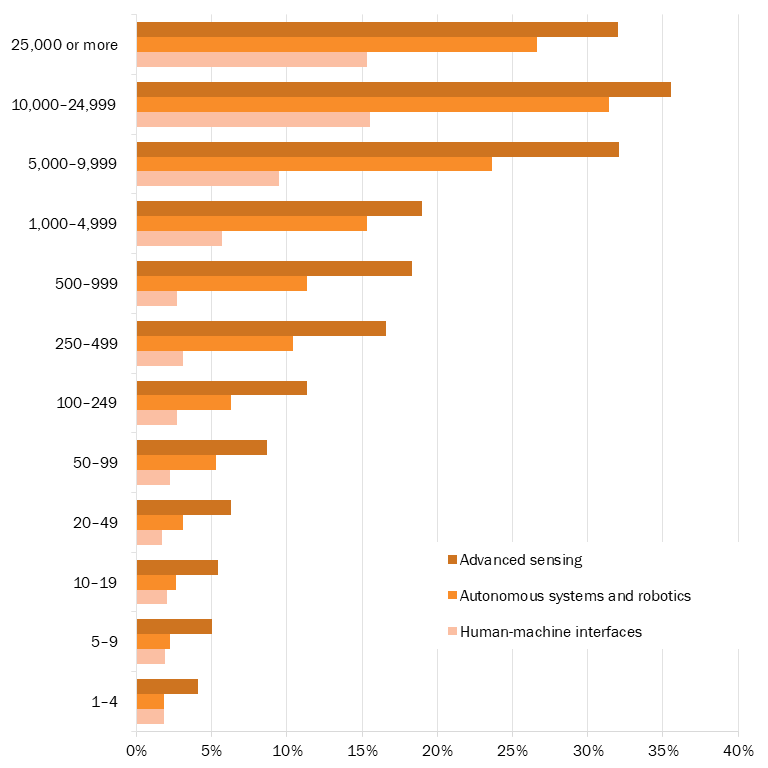

Figure 4 shows that companies with over 5,000 employees adopt workplace technology at significantly higher rates than do smaller companies across all technology categories. In effect, adoption that does exist is heavily concentrated among large manufacturing companies, leaving many American workers without access to beneficial workplace technologies.

This concentration creates a two-tier system wherein workers at large manufacturers gain safety and productivity benefits while workers at smaller companies and in service industries are left behind. The hospital scenario described earlier remains out of reach for most U.S. workplaces not because the technology does not exist, but rather because adoption incentives and support systems are inadequate.

Figure 4: Workplace technology adoption by company size, 2021[14]

Unlocking the Worker Upside of Technology

The framing of emerging workplace technologies as tools for employer oversight is only part of the story. When designed and deployed responsibly, these technologies offer measurable gains for workers’ safety, physical and mental health, and work experience. In addition to a short-sighted policymaker view on the future of work and lagging implementation, another problem is that the public debate around workplace technology too often ignores the worker benefits that are already materializing in certain sectors.

Preventing Worker Harm Before It Happens

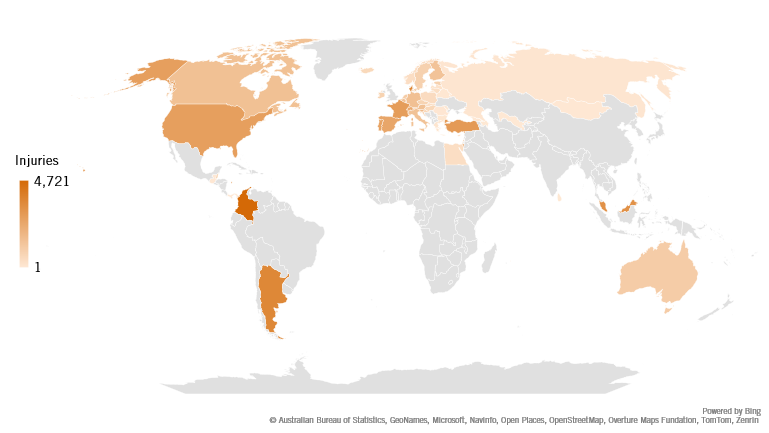

One of the clearest benefits of workplace technologies is injury prevention. Figure 5 shows that, in 2022, the median nonfatal occupational injuries per 100,000 workers across 52 nations with available data was approximately 686 workers.[15] Globally, the International Labor Organization estimated that in 2019, 374 million workers suffered from nonfatal occupational accidents, with lost work days leading to an estimated loss of 4 percent of the world’s gross domestic product.[16]

Figure 5: Non-fatal occupational injuries per 100,000 workers for all economic activity, 2022[17]

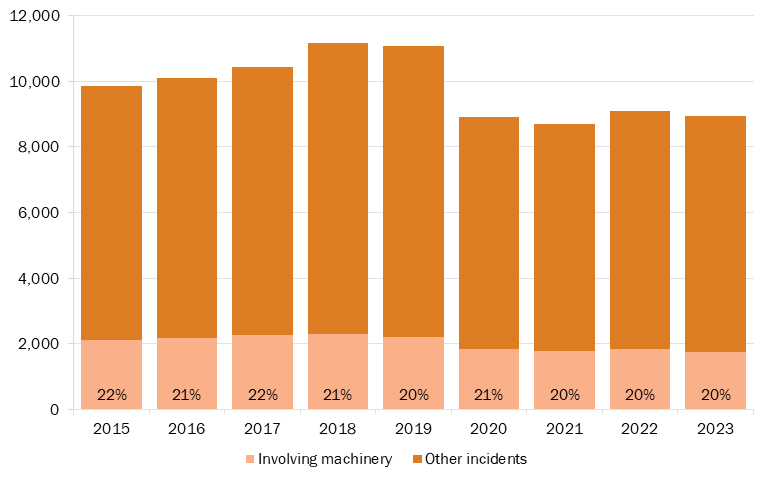

In the United States, between January 2015 and December 2023, the Occupational Safety and Health Administration (OSHA) recorded 18,312 machinery-related workplace injuries, such as workers getting “caught [or] entangled in running powered equipment.”[18]

The total number is likely much larger than 18,312 due to variables such as unreported injuries, but what is likely more accurate is machinery-related injuries make up approximately 21 percent of all severe injuries tracked. While, overall, severe injuries have slightly declined, machinery-related injury rates have remained stubbornly consistent, as shown in figure 6. The status quo will not solve this problem.

Figure 6: Percentage of workplace injuries involving machinery[19]

Other physical workplace risks do not materialize immediately. Repetitive strain from hand-intensive manufacturing processes or desk-bound work can lead to musculoskeletal disorders, eventually requiring rehabilitation surgeries.[20] Moreover, as a 2021 study shows, workers could face a variety of occupational risks ranging from exposure to allergens that could trigger pre-existing asthma to exposure to high UV that could cause eye injuries.[21] However, various types of workplace injuries are preventable when appropriate risk-mitigating measures are taken. Table 1 elaborates on a series of workplace risks and the interventions needed to prevent injuries.

Table 1: Occupational risks in different work environments, workers at increased risk, and risk-mitigating interventions[22]

|

Occupational risks |

Workers at increased risk |

Risk-mitigating interventions |

|

Asthma, COPD, respiratory infections, related diseases |

Workers with exposure to allergens and irritants |

Ventilation, pulmonary function testing, exposure monitoring, emission containment |

|

Behavioral, mental, or neurological disorders |

Workers in any work environment |

Identification of distress or mental illness; healthy work–life balance |

|

Cardiovascular diseases, ischemic heart disease, stroke |

Workers with exposure to lead, pollutants, or high stress environments |

Lead exposure monitoring and reduction; stress-reducing lifestyles |

|

Electrical hazard, electric shock, electrocution |

Electricians; workers in manufacturing, construction, agriculture, and power plants |

Ground-fault protection, electrical standards, hazard assessments, employee training, PPE |

|

Exertion, physical inactivity |

Workers in any work environment, particularly in offices and assembly plants |

Ergonomics, physical activity, lifestyle monitoring |

|

Eye injuries, cataract |

Outdoor workers, welders, carpenters; workers with high UV exposure |

Safety regulations, eye protection policies, eye wash stations, risk assessments, PPE |

|

Falls, slips, trips |

Workers in manufacturing, agriculture, construction, fishery, and mining |

Window guards, grab rails, lifelines, safety nets, lighting, equipment inspections, PPE |

|

Fire, heat, hot substances |

Firefighters, first responders; workers in mining, manufacturing, and construction |

Safety regulations, smoke detectors, fire suppression systems, evacuation plans, PPE |

|

Hearing loss |

Workers in mining, manufacturing, construction, and entertainment industry |

Limiting noise exposure, using noise-reducing controls, PPE |

|

Injuries from motor vehicles, mechanical forces, or road traffic |

Workers operating heavy machinery (e.g., in construction and industrial plants) |

Backup cameras, spotters, proximity detectors, driving laws, vehicle safety, drug testing |

|

Interpersonal violence |

Workers with frequent public interaction or handling cash |

Regulation, employee training, PPE |

|

Mesothelioma, melanoma, mouth or lung cancer |

Industrial, agricultural, and other workers exposed to carcinogens or radiation |

Exposure monitoring and reduction; capsulation and closed processes |

|

Musculoskeletal disorders |

Workers in agriculture, forestry, fishery, production, and service industry |

Ergonomics, specialized equipment and tools, adequate working hours, risk assessments |

|

Neonatal and congenital conditions |

Workers with exposure to certain chemicals and secondhand smoke |

Elimination of reproductive risks, engineering controls, no-smoke policies |

|

Repetitive motion with microtasks |

Workers in any work environment |

Ergonomics, regular breaks, monitoring of physical activity and lifestyle choices |

|

Skin diseases (e.g., contact dermatitis) |

Hairdressers, cosmetologists, cleaners, painters, health care workers |

Exposure monitoring; reduction of allergens or irritants; smoke-free policies, PPE |

|

Water-related incidents, drowning |

First responders; workers in boats, ships, ferries |

Safety rules, guard rails, evacuation plans |

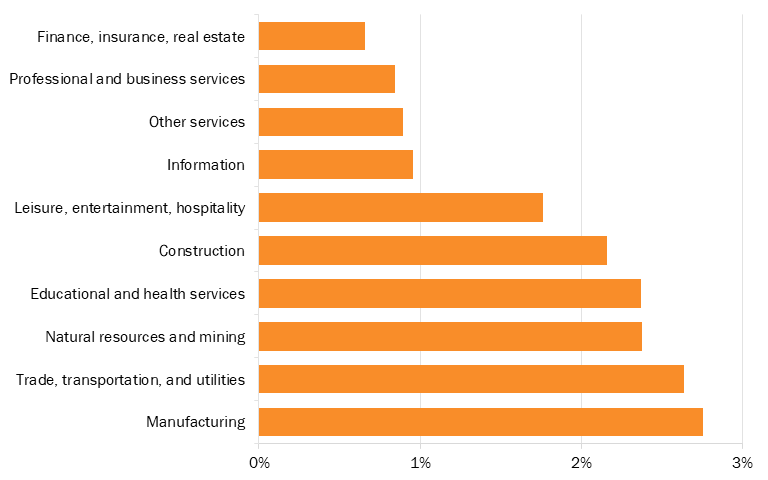

While all jobs carry some risk, Bureau of Labor Statistics (BLS) data shows that blue-collar workers likely face higher illness and injury rates than do white-collar peers.[23] Figure 7 shows that, in 2023, the top three industries with the highest share of workers with nonfatal injuries were manufacturing; trade, transportation, and utilities; and natural resources and mining.

Figure 7: Share of U.S. workers with nonfatal illnesses and injuries by industry in 2023[24]

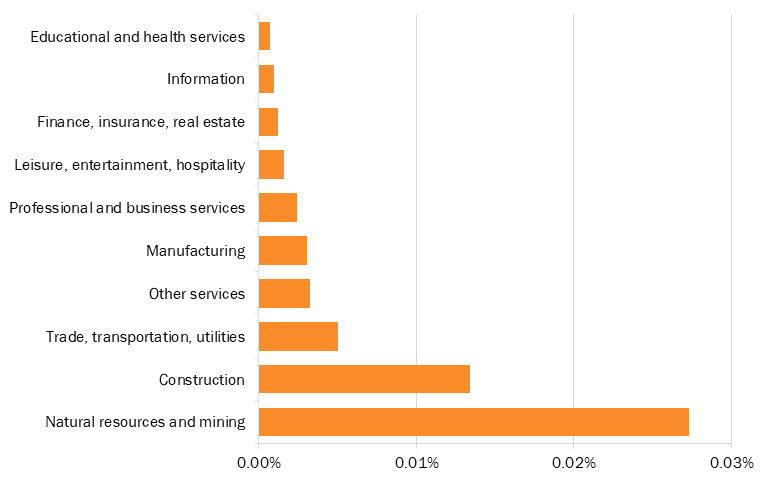

Similarly, the makeup of industries containing the highest share of workers with fatal illnesses and injuries further suggests that blue-collar workers face greater workplace risks. As figure 8 shows that, in 2023, natural resources and mining had a fatal injury rate of 0.03 percent, construction had a rate of 0.01 percent, and trade, transportation and utilities had a rate of 0.005 percent.

Figure 8: Share of U.S. workers with fatal illnesses and injuries by industry, 2023[25]

Data-rich technologies integrated into clothing or machinery can detect hazards and anticipate risks before incidents occur. For example, embedded Internet of Things (IoT) sensors can alert workers if their limbs or clothing are close to a dangerous rotating band.[26] Depending on implementation, sensors could sound a preemptive warning or trigger a process slowdown.[27] These tools shift manufacturing safety from reactive compliance to proactive intervention.

Wearable sensors and ergonomic algorithms can flag risky movements or overexertion before they lead to injury and recommend suggested breaks, workplace optimizations, or posture corrections.[28] For example, the National Safety Council (NSC), a nonprofit organization focused on eliminating the leading causes of preventable death and injury, has highlighted Amazon’s ErgoPick, an ergonomic picking assistance software, for helping reduce musculoskeletal disorders and back pain, as well as Pacific Gas & Electric Company’s Etiscope, for using wearable sensors to provide ergonomics risk assessments and real-time feedback for frontline and other industrial workers.[29]

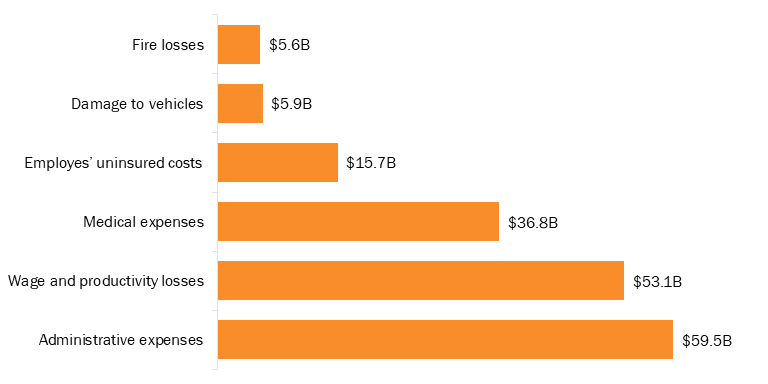

These individualized systems offer a major upgrade from traditional workplace safety interventions, generic safety protocols, and self-reported discomfort.[30] Furthermore, they can help reduce disability claims, absenteeism, and long-term health costs.[31] As a result, the United States could save billions each year. As NSC noted, the cost of workplace injuries and illnesses cost $176.5 billion in 2023.[32] Figure 9 shows a breakdown of workplace injury costs.

Figure 9: Costs of workplace injuries, 2023[33]

Reducing Worker Stress and Burnout

Emerging workplace technologies can reduce cognitive strain and workplace stress. High-pressure professions such as nursing, trucking, and emergency response can particularly benefit from tools that monitor fatigue or optimize scheduling.[34]

In hospitals, adaptive scheduling systems can reduce burnout by balancing workloads.[35] In logistics, fatigue-detection systems integrated into vehicle cabins have shown promise in reducing crash risk and occupational fatigue among long-haul truckers.[36] Biofeedback-enabled wearables can also offer workers real-time insight into physiological signals of stress, encouraging healthier self-regulation and flagging concerns to employers when appropriate.[37] With responsible implementation and clear boundaries for data use, these systems can deliver real mental health benefits.

Critics have often pointed out that electronic and performance monitoring or always-on communication tools can give workers a sense of pressure or loss of autonomy.[38] These concerns are not unfounded, especially when combined with poor deployment, and deserve consideration.

Yet, ignoring the potential mental health benefits of technology would also be shortsighted. As of now, the mental health upside is underexamined in federal discussions, such as in the 2024 GAO report. As policymakers consider how to regulate the use of workplace technology, understanding and encouraging its positive use cases should be part of the equation.

Making Hard Work More Sustainable

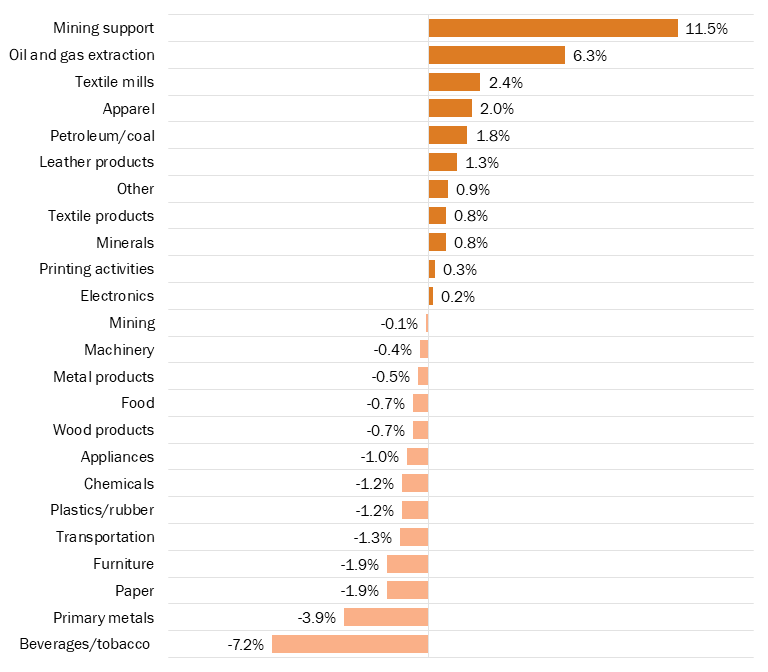

Across industries, emerging workplace technologies are helping workers complete more complex or physically demanding work with greater speed and precision. As shown in figure 10, the few U.S. industries to achieve sustained labor productivity gains in recent years include oil and gas extraction, support activities for mining, and textile mills. These industries share the common feature of having adopted more automation, remote monitoring, and digital workflows.[39]

Figure 10: Average annual change in productivity growth in manufacturing and mining industries, 2019–2023[40]

These innovations allow employers to produce more output with less manual effort. In oil and gas, for example, productivity rose 6.3 percent from 2019 to 2023, due in part to advanced drilling, predictive analytics, and remote operations centers.[41] Similarly, textile mills saw productivity increase by 2.4 percent thanks to robotics, smart looms, and automated quality control.[42] These cases show that when workplace technologies are thoughtfully deployed, they not only make work safer and less physically taxing—they also generate measurable economic value.

Technology that augments physical labor is especially promising in industries where injuries and fatigue are common. Exoskeletons and wearable powered suits, for example, can reduce strain and increase endurance. In one retail pilot, grocery workers wearing back-support exosuits completed 8 percent more work per shift and reported 30 percent less back pain.[43] In warehouse settings, augmented-reality (AR) glasses and heads-up displays have boosted speed and accuracy by guiding workers step-by-step on tasks.[44] DHL Supply Chain reported a 25 percent faster picking process when warehouse staff used AR smart glasses.[45] In hazardous industries such as construction or manufacturing, these systems reduce mental and physical burden in repetitive or risky work.[46]

Since the mainstream advent of generative AI models began in 2023, productivity gains have accelerated in many white-collar workplace settings.[47] AI tools have streamlined document review, code generation, and customer support workflows, allowing employees to offload routine tasks.

However, as figure 10 shows, many U.S. industries saw negative productivity growth from 2019 to 2023, despite years of available workplace technology. These gaps are a result of uneven adoption. Industries such as manufacturing and mining often remain constrained by legacy infrastructure and face higher barriers to deploying new tools.[48] Closing this gap is not just about AI readiness, but also about investing in workplace-integrated systems that meet sector-specific needs. This is where targeted policy support can have an outsized impact.

The concern that workplace technologies might intensify work pace rather than improve conditions also deserves consideration. Increasing worker productivity is a worthwhile goal, and higher productivity can lead to higher wages. However, critics accurately point out that efficiency gains can sometimes translate into unreasonably higher output expectations.[49] If employers use monitoring systems primarily to push workers beyond reasonable workloads, it may result in increased stress or job insecurity. But when the same technologies are deployed with the goals to identify and eliminate unnecessary strain, reduce errors, or provide better support, workers benefit alongside employers. Policymakers can set an example in this regard by tying workplace technology policy to safety and well-being goals in addition to productivity goals.

Worker Quality-of-Life Gains

Employers benefit from productivity-enhancing technologies through greater output per worker, fewer errors, and reduced injury-related disruptions. Yet, when implemented responsibly, these technologies also deliver meaningful value to workers. The most immediate impact comes from better on-the-job support. In physically demanding jobs, augmentation tools such as exoskeletons reduce strain, while wearable guidance systems reduce mental load by streamlining instructions. These tools do not eliminate hard work, but they can make it more tolerable and sustainable.

In many settings, workplace technologies are less about transforming the job itself and more about reducing the friction of repetitive, stressful, or error-prone tasks. When algorithmic management systems are designed well, they can help automate monotonous workflows or optimize scheduling in ways that reduce unnecessary downtime and inefficiency. That may not shorten an eight-hour shift, but it can mean fewer avoidable mistakes, smoother collaboration, and less stress from chaotic or poorly coordinated processes. These are subtle but real quality-of-life improvements that matter, especially in physically demanding or high-pressure sectors where worker burnout and turnover are high.

Workplace technology also has the potential to improve working conditions, offering greater flexibility and creating fairer performance systems. According to a 2023 Pew survey, 71 percent of remote-capable workers reported better work-life balance when able to work from home.[50] While not all jobs can be remote, flexible scheduling enabled by workforce management software can extend some of these benefits to frontline and shift-based workers.[51]

Data-driven tools can also make performance evaluations more transparent and merit-based. When workers have visibility into the metrics that define success, and when those metrics are grounded in consistent, objective data, the result is greater trust.[52] Productivity trackers, personalized performance feedback systems, and skill development platforms can help workers understand expectations, track progress, and receive recognition for high performance.

It is also important to recognize that expectations of privacy differ substantially between work and nonwork settings. Employees already work in environments where part of the job itself is managers continually observing and evaluating their performance. Using data to ensure that workers perform their duties effectively mirrors a supervisor physically observing them and—if designed and implemented well—makes the process more consistent, scalable, and evidence-based.

Expanding Access to Work

Workplace technologies hold significant promise for expanding access to work, particularly for demographic groups historically marginalized in traditional labor markets. For older adults, people with disabilities, and workers with physical constraints, workplace technologies can enable workforce participation. As the U.S. workforce continues to age and labor force participation among people with disabilities remains disproportionately low, policymakers should see workplace technology as a lever for inclusion, not just a surveillance risk.[53]

Wearables, sensors, and AI-driven interfaces can help more Americans work safely, effectively, and longer. For example, digital workflows can reduce the need for repetitive physical labor, and predictive scheduling systems or remote work infrastructure can accommodate medical or caregiving needs.[54] Research suggests that automation and assistive technologies have the potential to enable “longevity work” by aligning job design more closely with the needs of aging workers, especially if they are high-skilled.[55]

Even for those who are not formally classified as disabled, robotic technologies can extend careers by offsetting physical decline and reducing injury risk. Exoskeletons are enabling assistive ambulation for patients who have undergone spinal cord injury and reducing strain on warehouse and construction industry workers’ backs and shoulders.[56] These technologies can delay retirement, lower turnover, and reduce the need for retraining, while making physically demanding jobs more humane.

Workplace technology can act as a force multiplier for inclusion and expanding accessibility. But realizing these benefits will require policymakers to shift their focus beyond privacy and surveillance concerns alone to also consider workplace technology policy in conversation with economic participation and inclusive growth. This is an economic and social opportunity. Millions of working-age adults with disabilities remain unemployed or underemployed despite being willing and able to work.[57]

According to the Department of Labor (DOL), 4 in 10 adults with disabilities ages 16 to 64 were either working or actively looking for work in 2024.[58] Yet, people with disabilities face challenges finding work. Despite the 2024 unemployment rate in the United States being at about 4 percent, the unemployment rate for people with disabilities was about 8.1 percent for those ages 16 to 64, signaling that people with disabilities want to work but have a harder time finding a job partly because they face more workplace challenges.[59] However, with the right policy support, workplace technologies could narrow this gap.

What Data Workplace Technologies Actually Collect

Emerging workplace technologies do not only collect large volumes of data about workers but also new types of data that can reveal previously private aspects of the human experience, such as a worker’s level of fatigue. As data-rich technologies come into use across workplaces, policymakers should clearly understand what data these systems collect so that they can create effective regulation.

Workplace Technologies Collect Novel Types of Data

Biometric data includes physiological signals such as heart rate, body temperature, respiratory function, blood glucose levels, and hydration.[60] These data types are foundational to applications in real-time health monitoring, early illness detection, and fatigue risk management, and are collected in physically demanding or high-risk occupations such as logistics, utilities, and construction.[61]

Ergonomic wearables, vision systems, and connected tools capture movement and postural data. These data streams reflect how workers move, analyzing their lifting angles, joint strain, repetitive motion patterns, and overall muscular exertion.[62] Cognitive and mental state data offers insight into workload strain, emotional regulation, and mental acuity. These data types are often more sensitive but offer potential applications in preventing burnout or cognitive overload in fields such as air traffic control and technical operations.[63]

Behavioral and productivity data such as system usage patterns, workflow traces, and digital engagement metrics can help optimize processes, identify friction points, and personalize task support through AI software platforms.[64] Environmental exposure data, captured via workplace infrastructure sensors, tracks air quality, temperature, noise, and exposure to harmful substances.[65] Real-time physical location and proximity data track workers’ positions within a facility or site, often using GPS, RFID, or Bluetooth sensors.[66] These data streams can enhance safety by ensuring that employees remain in safe zones, avoid workplace violence, and manage equipment usage in shared spaces.[67]

How Workplace Technology Data Varies

Not all workplace data is equally sensitive, and different types of data carry different potential for misuse or benefit. Biometric and mental state data, for example, can reveal highly sensitive personal information and may demand stronger protection. Ergonomic and environmental data, such as movement patterns or air quality, can be relatively lower-risk and offer clear benefits in driving down workplace injuries or fatigue.

Employers collect workplace data through both passive and active mechanisms. Passive collection involves background monitoring that requires no worker input, such as wearable sensors tracking posture and ambient cameras scanning for safety hazards.[68] Active collection relies on worker interaction, such as completing self-reports or logging task progress.[69] Many emerging systems use a hybrid model, combining passive sensor data with active inputs to refine accuracy.[70]

Understanding these distinctions is important when evaluating systems for fairness and psychological impact. For instance, a wearable that quietly monitors hydration levels in warehouse workers and only issues alerts when thresholds are breached would likely make for a helpful safety tool, whereas a system that flags every missed keystroke in a software developer’s code could quickly become counterproductive.

No One-Size-Fits-All Approach to the Workplace

Layered atop these distinctions are sectoral factors such as regulatory intensity, safety risks, and performance measurement norms. One example is that an AI camera in a meatpacking plant may primarily prevent injuries, whereas the same technology in a customer service environment may focus more on workflow efficiency and error reduction. As a result, a one-workplace-fits-all policy approach to workplace technology is likely to miss critical nuances.

The distribution of labor and capital to the workplace is also important. In labor-intensive workplaces, such as a factory with workers picking items off an assembly line, technologies are often deployed to better standardize worker output and lower skill requirements.[71] On the other hand, in more capital-intensive work environments, such as a factory with robots already performing tasks and workers in more skilled roles that work to manage the robots, workplace technologies are generally more used to increase workers’ flexibility and already-high levels of skills.[72]

Given this complexity across workplaces, policymakers should think strategically about which types of work environments stand to benefit the most from thoughtful technological integration, and where policy intervention is most needed to support both innovation and worker well-being.

Reframing the Workplace Technology Debate

Despite the real promises that workplace technologies offer, public and policy discourse remains focused on two concerns: job automation and worker surveillance. Job loss due to automation is frequently cited but ultimately overstated.[73] A large body of economic research shows that technological adoption tends to shift labor demand rather than eliminate it outright.[74] New roles are created even as others change or disappear, and workers, including those in lower-skilled jobs, generally benefit over time through increased productivity, wages, and workplace safety.[75] Given the depth of existing work on automation, this report focuses on the second, and less debated, policy concern: surveillance.

The problem is not surveillance itself, but rather how the term is used. Describing any data-collecting workplace technology as “surveillance” muddles the distinctions between technologies, data types, and workplaces in question. A more appropriate framework would recognize the current moment as a continuation of the digital transformation of the workplace. One example would be the shift of the 1990s and 2000s, when email, enterprise software, and Internet connectivity redefined white- and blue-collar work alike.[76] Emerging tools such as wearables, edge computing, AI, and connected sensors are likewise not inherently dystopian.

Some monitoring tools serve clear public interest functions in the workplace. Real-time telemetry in warehouse forklifts prevents collisions.[77] Heat stress sensors can trigger alerts before a worker suffers from heatstroke. These are examples of safety technologies.[78] Collapsing them into a general fear of monitoring obscures their benefits and may disincentivize adoption.

That said, even the most well-intentioned uses of workplace technology raise legitimate questions about privacy, transparency, and governance. However, the role of government is not to police bad management or enforce corporate best practices. Instead, wherever data collection enables monitoring that is hidden, excessive, not justified by or clearly misaligned with worker benefits, policymakers have a role to play.

Design Flaws in Emerging Workplace Technologies

It is important to acknowledge that many workplace technologies are still maturing. Issues such as poor sensor calibration, false positives, and unreliable data quality remain widespread in many real-world work environments.[79]

Consider a long-distance driver evaluated by an app that monitors speed, braking patterns, and rest periods. If the driver slams on the brakes to avoid a deer that jumps into the path of the truck, their safety score may drop. In this case, the problem is not that the employer records the data. Instead, this case raises two separate problems. First is the technological need for workplace technologies to evolve from static tools into adaptive systems that better incorporate human judgment and contextual awareness. False positives where legitimate or even exemplary behavior is unfairly penalized show how poorly designed workplace technologies, especially those based on narrow rules, can misunderstand signals.

Second, even when data is accurate and includes the necessary context, how employers use that data may be flawed or unfair. Policymakers should recognize both of these potential gaps: technological and governance.

Well-designed future systems will better incorporate environmental and other types of data to contextualize behavior. But until systems can reliably do that, workers should ideally have clear processes to challenge or explain flagged incidents, particularly when these flags affect job security or pay. Due process should not be an afterthought in digital workplaces.

Policymakers have a role to play here. Government research funding and procurement requirements can encourage user-centered design principles, ensuring that systems do not just optimize for managerial oversight but also serve workers. Public-sector leadership could help reorient the market toward systems that balance performance tracking with fairness and reliability.

A Smarter Regulatory Lens For Workplace Technology

As discussed ahead, recent legislative efforts to regulate workplace technology reflect growing anxiety about surveillance and algorithmic management. While some of these concerns are real, many proposed laws risk overcorrecting without accounting for the potential benefits for workers.

In other areas of regulation, the government has an important role in funding independent technical validation of algorithmic tools used in employment, much like the Food and Drug Administration (FDA) evaluates medical devices.[80] A similar model could help inform oversight of high-impact algorithmic tools in employment. Today, most audits and impact assessments are employer funded and lack consistent standards.[81] Government-backed technical validation for workplace technology used in high-stakes contexts such as hiring and disciplinary decisions could promote trust without requiring new and rigid mandates. This would also help distinguish those tools against low-risk applications such as automated interview scheduling, allowing regulations to focus oversight on the former without burdening the latter.

On the other hand, policymakers should avoid intervening where market incentives already discourage bad behavior. For example, proposals discussed ahead would prohibit the use of basic productivity tracking tools such as keystroke monitors.[82] While some employers certainly misapply these tools, more employers already avoid overuse because doing so undermines morale, creates retention issues, and leads to costly reputational backlash.[83]

Legislative and regulatory pressures are not the only forces that can slow workplace technology adoption. Third parties, including labor organizations, can also shape technology deployment in deleterious ways. For example, certain union contracts, such as provisions negotiated by the International Brotherhood of Teamsters with United Postal Service, give unions the right to review any new technological solutions before implementation.[84] Similarly, longshore unions have actively opposed the introduction of automation at U.S. ports.[85] Any comprehensive policy framework should therefore account for the influence of these third parties, balancing worker protections with the need to deploy technology that improves safety, productivity, and overall job quality.

Most legislative proposals lack a forward-looking perspective on how digital tools can benefit workers. Besides OSHA requirements, no laws affirmatively encourage the use of data for injury prevention, hazard detection, or improved work conditions.[86] Instead of default prohibitions, lawmakers should design “safe harbor” provisions that enable experimentation with workplace technologies, provided they meet baseline fairness, transparency, and safety standards. This would encourage employers to adopt beneficial innovations while providing workers with clear protection.

State Legislation Is Distrustful by Default

Recent state-level legislative proposals aimed at workplace technology reflect a growing discomfort with employer technology use, regardless of context.

For example, California’s 2022 Workplace Technology Accountability Act would have required employers to conduct detailed algorithmic impact assessments covering virtually every use of employee data, regardless of context or risk.[87] It defined “electronic monitoring” so broadly that it could include innocuous systems such as badge swipes or logistics software. More recent bills such as “SB-7 Employment: automated decision systems” and “AB 1331 Workplace surveillance” in California also continue this trend.[88] For example, AB 1331 threatens the use of badge data for performance coaching or operational insights by imposing broad restrictions on “off-duty” data, which could include routine interactions on-site, such as scanning a badge for access to amenities.

Similarly, New York’s 2024 proposed Bossware and Oppressive Technologies Act would have banned employers from using algorithmic systems as the “primary basis” for employment decisions.[89] That would not distinguish between opaque surveillance and tools designed to reduce bias or support safety.

While these bills are framed as protective, they reflect a deeper mistrust of workplace technology itself, often defaulting to assuming that all data collection is suspect, even when that data could be used to proactively prevent accidents or monitor fatigue.

Illinois’s Biometric Information Privacy Act (BIPA) attempts to regulate biometric data such as fingerprints and facial scans.[90] On its face, BIPA appears well-intentioned: it requires employers to get consent before collecting such data and mandates that it be stored securely. However, in practice, BIPA has become a cautionary tale in how privacy laws can go wrong. Following a 2019 Illinois Supreme Court ruling that allowed individuals to sue even without showing harm, BIPA triggered a surge of lawsuits.[91] Class actions have ballooned into high-cost settlements, often with the payouts going to attorneys rather than affected individuals. This litigation wave has chilled legitimate technology use in Illinois workplaces and discouraged small businesses from adopting timekeeping and access systems that rely on biometrics, which prevents fraudulent time tracking (e.g., buddy punching, where one employee clocks in or out for another) and creates more convenience for employees, who do not have to remember passwords. The result is a law with flawed incentives.

The lesson from BIPA and more sweeping proposals in California and New York is that poorly scoped privacy regulation can make it harder, not easier, to protect workers. To move forward, state lawmakers should prioritize filling narrow policy gaps that require government intervention but are too niche to make legislative progress at the federal level.

Federal Legislation Thus Far Is a Missed Opportunity

At the federal level, proposed legislative efforts reflect legitimate concerns about privacy and digital oversight, but suffer from the flaw of framing workplace technology as invasive surveillance. Bills such as the Stop Spying Bosses Act and the No Robot Bosses Act, both introduced over the last two years by Representatives Chris Deluzio (D-PA) and Suzanne Bonamici (D-OR) in the House and former Senator Bob Casey (D-PA) in the Senate, aim to restrict or mandate disclosures around data use but fail to distinguish between surveillance that is punitive and opaque versus monitoring that is aimed at positive goals such as injury prevention and fatigue management.[92]

There are already some important protections already in place. Federal antidiscrimination laws such as Title VII of the Civil Rights Act and the Americans with Disabilities Act (ADA) prohibit employment practices that have disparate impact or unfairly target protected groups.[93] This means that if a workplace algorithm, for example, uses biometric or behavioral data in a way that disproportionately disadvantages people of color or people with disabilities, employers could be vulnerable to litigation. Similarly, the National Labor Relations Act (NLRA) protects workers’ rights to organize and prohibits employer actions that interfere with collective activity.[94]

Putting checks on the primary use of algorithmic systems in hiring or performance reviews can make sense in high-risk contexts, but applied too broadly, these rules could prevent employers from using even well-validated models to identify skill gaps or reward high-performing employees. For example, technology such as Canditech’s platform and others that help assess skills and reduce subjectivity in hiring could be implicated.[95] Moreover, these bills risk promoting human discretion as a gold standard, despite ample evidence that human managers are themselves prone to bias, inconsistency, and opacity.[96]

What is missing in the federal legislative landscape is how data-rich technologies could affirmatively improve worker outcomes. The government is doing too little to seed public-private partnerships that could demonstrate how data-rich workplaces can yield measurable improvements in health, safety, and worker convenience.

At the same time, there are areas where the federal government should tread carefully or stay out altogether. Federal intervention should not substitute for internal corporate governance, private sector codes of conduct, or collective bargaining agreements that reflect the specific needs of different workplaces.

Ultimately, the federal role should not be to ban or bureaucratize workplace technology, but rather to set a floor by creating guardrails and incentives for it to be used responsibly. This includes ensuring that workers have agency and voice in how technologies are deployed, companies are rewarded for responsible data use, and the technologies with the greatest potential to reduce injuries, burnout, and inequality are scaled.

The Current Standards Regime is Unfit For the Modern Workplace

OSHA plays a critical role in setting binding workplace safety standards.[97] These rules carry legal force, and noncompliance can result in fines, mandatory remediation, or criminal penalties. OSHA standards shape employer behavior, define what is safe, and set the floor for industry practices.

But OSHA’s authority is constrained by scope and speed. Because its standards must be evidence-based and undergo a rulemaking process, they often lag behind the fast rate of developments in workplace technology.[98] For example, OSHA’s standards cover personal protective equipment, ventilation, and exposure to harmful substances, but offer little guidance on technologies already reshaping modern workplaces, such as sensor-based monitoring systems, wearables, biometric fatigue detection, and AI-driven safety analytics.[99]

In construction, OSHA’s standard for “General Safety and Health Provisions” requires training and hazard mitigation but does not mention real-time sensing or AI tools already being deployed on worksites.[100] Similarly, standards for noise exposure and radiation omit provisions for using wearable tech to detect and log these exposures continuously.

This regulatory lag creates a two-tier system. Forward-looking companies that want to modernize may find little regulatory guidance, while laggards face no pressure to modernize beyond legacy methods. Startups and researchers developing category-creating workplace technologies face a dilemma: the lack of prescriptive standards offers theoretical freedom but in practice deters investment and slows the commercialization cycle.

Designs Standards Lack Focus and Relevance

While OSHA governs workplace safety, it does not cover how safety technologies are designed. In this vacuum, voluntary standards bodies such as the International Organization for Standardization (ISO), the American National Standards Institute (ANSI), and ASTM International have developed voluntary technical standards for the design of physical systems such as wearable robotics and safety equipment.[101] However, their reach is limited and mismatched with the needs of real-world workers.

ISO 13482, for instance, addresses safety for personal care robots and was never intended for heavy-duty industrial use.[102] Likewise, ASTM’s F48 committee on exosuits is one of the few efforts tailored to labor settings, but its influence remains limited by slow adoption and voluntary uptake.[103]

Meanwhile, the U.S. government has failed to fully use its considerable leverage as a funder and buyer to shape the development of these technologies. Federal agencies that fund R&D have long supported exoskeletons and human augmentation in military and health contexts but have rarely aligned their investments toward labor market needs or workplace applications.[104]

Policy Recommendations

Workplace technologies are evolving rapidly, but policy discussions too often frame them narrowly as surveillance tools rather than recognizing their potential to improve safety, health, and productivity. To shift this conversation and ensure a balanced approach, policymakers at all levels should focus on clarifying lawful uses of workplace data, incentivizing responsible innovation, and embedding worker voices in technology deployment. Increasing both the R&D of workplace technologies and their responsible adoption across the U.S. economy is critical to unlocking the technology’s upside at scale. The following recommendations outline steps federal, state, and local governments can take to establish guardrails, accelerate adoption of beneficial tools, and build trust in data-rich workplaces.

1. Add Clarity Through a Federal Framework

Congress should task DOL, in coordination with the Federal Trade Commission and other relevant agencies, to develop a federal workplace technology framework that complements broader privacy legislation while addressing the unique dynamics of the employer-employee relationship. This framework should focus on clarifying for employers any nonpermissible uses of workplace data under existing law and recommended best practices for lawful uses, explaining to employees their rights and expectations, and advising Congress to focus on clarifying lawful uses of workplace data so that employers can deploy workplace technologies to serve legitimate operational needs while preventing generalized surveillance.

This framework should clearly distinguish between employer-deployed technologies and personal consumer devices, such as fitness trackers and smartwatches, to avoid regulatory overreach while maintaining focus on workplace-specific data flows. As a forward-looking structure, this policy should align with any future federal privacy legislation, ensuring consistency while preserving the distinct considerations of the workplace context. The framework should also codify clear definitions for data collection, electronic monitoring, and surveillance.

Crucially, the framework should be shaped through a transparent, consultative process that ideally would include input from a broad range of stakeholders, including workers and worker advocacy groups. DOL can play a key role by creating structured opportunities—such as public comment periods, listening sessions, and targeted outreach to underrepresented sectors—for workers to share their perspectives on how technologies affect safety, autonomy, and job quality.

2. Increase Workplace Technology R&D

To complement a federal workplace technology framework, the federal government should expand R&D efforts for workplace technology. DOL, working in partnership with the National Science Foundation (NSF), should create a dedicated fund for rigorous field-testing and pilot programs focused on technologies that improve job quality, safety, and accessibility. These tools should be platform agnostic to ensure broad usability across devices and environments.

Simultaneously, the U.S. Census Bureau should expand its Annual Business Survey to gather more precise data on where and how workplace technologies are being deployed across industries and firm sizes. This data is essential to shaping targeted, evidence-based policy interventions and avoiding overgeneralizations based on high-profile companies alone.

3. Leverage Procurement Power

The federal government should also utilize its role as the nation’s largest employer and buyer to accelerate responsible workplace technology adoption. Through executive action, the White House should direct agencies such as the Office of Personnel Management, Department of Defense, and Department of Health and Human Services to pilot safety-enhancing and productivity-boosting technologies in public-sector workplaces. Procurement should be coupled with open reporting on worker outcomes and post-deployment evaluation to ensure that technology adoption produces measurable benefits without introducing unintended risks.

4. Modernize Workplace Safety Standards

Policymakers should modernize workplace safety standards to foster innovation without compromising worker protection. Rather than mandating specific tools, OSHA should adopt flexible, outcome-based standards that define what workplace technologies must achieve while allowing companies to choose how to meet those goals. These standards should include basic worker protections such as transparency, data security, and anonymization provisions where feasible. Tiered frameworks that reward voluntary, tech-enhanced safety programs can further incentivize adoption, following the successful model of OSHA’s Voluntary Protection Programs.

To complement this, the federal government should establish a cross-agency initiative led by OSHA in partnership with NIST and NSF to develop integrated design standards into the R&D incentives for workplace technologies. By coordinating standards and investment strategies across agencies, the United States can reduce regulatory ambiguity and create a foundation for workplace technology design standards.

Ultimately, the U.S. government should update standards for workplace technology through the use of federal procurement and grant-making to incentivize responsible design. Voluntary standards, while helpful, are not enough on their own. Without relevance to real-world labor conditions, these standards risk becoming a checklist for compliance rather than a foundation for safer and better-performing workplace technology.

5. GAO Should Focus on Potential Positive Outcomes

GAO has stated that its 2024 report will be followed by another report that “will incorporate stakeholder interviews and a literature search to enhance the information related the uses and impacts of digital surveillance. Additionally, it will address how federal agencies oversee employers’ use of digital surveillance technology.”[105]

The follow-up GAO report should explicitly examine not only potential risks but also the benefits and positive impacts of digital monitoring and other next-generation workplace technologies. Accountability should include not only identifying harms but also assessing whether federal agencies are effectively using advanced data-driven tools to improve worker safety, health, productivity, and inclusion across the federal workforce. By evaluating both risks and benefits, GAO can provide a more balanced perspective that informs policymakers on how to maximize the potential of workplace technologies for employees throughout government operations.

6. Reshape Public Conversation on Surveillance

The federal government has a role to play in reshaping public conversation around workplace technology. To counter simplistic narratives equating all monitoring with harmful surveillance, DOL and OSTP should publish clear guidance that distinguishes protective technologies from invasive ones. A roundtable comprising technologists, labor representatives, and employers should develop shared norms and model language for the responsible use of workplace data. Policymakers from agencies such as DOL and OSTP should issue clear public guidance that reframes data-driven workplace technologies as potential tools for safety, equity, and productivity and not inherently surveillance tools.

To further promote responsible technology use without deterring adoption, DOL should establish a Workplace Technology Accountability Bureau (WTAB) that acts as a nonregulatory, independent office modeled on the Better Business Bureau. This entity would serve as a trusted, centralized hub where workers, unions, and whistleblowers could anonymously report concerns about misuse of workplace technologies. Rather than enforcing penalties, the WTAB would focus on transparency and public trust by investigating complaints, surfacing best practices, and issuing voluntary trust grades for companies based on their adherence to principles such as transparency, data minimization, and worker engagement. Importantly, these evaluations would distinguish between beneficial, safety-enhancing tools and systems that raise legitimate concerns around privacy.

7. Expand Data Collection on Workplace Technology Adoption

Congress should direct the U.S. Census Bureau, in coordination with DOL and NIST, to collect more detailed, sector-specific data on the adoption of next-generation workplace technologies in the private sector. Surveys should capture information on technology type, purpose, scale of deployment, and workforce demographics across diverse labor arrangements. Integrating this data with existing BLS, OSHA, and Census datasets would allow for more evidence-based analysis of how these technologies affect worker safety, productivity, and inclusion. Regular collection and public reporting of these findings would provide policymakers and researchers with the insights needed to design targeted incentives, R&D programs, and technical assistance, while ensuring federal policy is informed by the actual use and impact of workplace technologies.

8. Target State and Local Policies at High-Risk Uses

State and local policymakers could, for example, require reporting or impact assessments only for technologies used in high-risk or high-stakes contexts, while providing incentives to adopt tools that demonstrably improve safety, reduce injury, and support inclusion. By adopting a context-sensitive approach, state and local governments can protect workers without discouraging adoption of technologies that deliver measurable benefits.

Conclusion

Once again, imagine a hospital in the near future—but in a world wherein the U.S. government has failed to act. The technology for automated systems that can alert emergency room staff about incoming patients’ ailments exists but has not been adopted by the hospital because no incentives existed to develop or validate it. Staff have wearable health monitors, but instead of preventing fatigue, they are used to pressure staff into skipping breaks in an absence of legal red lines. The technologies that could help reduce worker injury and burnout exist, but without policy guardrails or public investment, they are either missing or misused. This is the future the United States risks: one in which innovation still happens, but its benefits bypass the very workers it was meant to support because policymakers have demonized the technology and waited too long to support it.

Acknowledgments

The author would like to thank Daniel Castro, Trelysa Long, and Justin Riggi for assisting with this report. Any errors or omissions are the author’s alone.

About the Author

Eli Clemens is a policy analyst focusing on e-commerce and retail technology policy at ITIF’s Center for Data Innovation. Previously, he worked as an open source intelligence analyst and served as a Peace Corps volunteer in China. He holds a master of International Affairs degree from Columbia University’s School of International and Public Affairs and a B.A. from New York University.

About the Center For Data Innovation

The Center for Data Innovation studies the intersection of data, technology, and public policy. With staff in Washington, London, and Brussels, the Center formulates and promotes pragmatic public policies designed to maximize the benefits of data-driven innovation in the public and private sectors. It educates policymakers and the public about the opportunities and challenges associated with data, as well as technology trends such as open data, artificial intelligence, and the Internet of Things. The Center is part of the Information Technology and Innovation Foundation (ITIF), a nonprofit, nonpartisan think tank.

Contact: [email protected]

datainnovation.org

Endnotes

[1]. Mohammad Moshawrab et al., “Smart Wearables for the Detection of Occupational Physical Fatigue: A Literature Review,” Sensors 22, no. 19 (2022): 7472. DOI: 10.3390/s22197472.

[2]. Ibid.

[3]. U.S. Government Accountability Office (GAO), “Digital Surveillance of Workers: Tools, Uses, and Stakeholder Perspectives” (Washington DC: GAO, August 2024), https://www.gao.gov/assets/880/870838.pdf.

[4]. “Request for Information; Automated Worker Surveillance and Management,” Science and Technology Policy Office (OSTP), accessed September 2025, https://www.federalregister.gov/documents/2023/05/03/2023-09353/request-for-information-automated-worker-surveillance-and-management.

[5]. GAO, “Digital Surveillance of Workers: Tools, Uses, and Stakeholder Perspectives.”

[6]. GAO, “‘Why do I feel like somebody’s watching me?’ Workplace Surveillance Can Impact More Than Just Productivity,” GAO, October 29, 2024, https://www.gao.gov/blog/why-do-i-feel-somebodys-watching-me-workplace-surveillance-can-impact-more-just-productivity.

[7]. “Request for Information; Automated Worker Surveillance and Management,” OSTP.

[8]. GAO, “Digital Surveillance of Workers: Tools, Uses, and Stakeholder Perspectives.”

[9]. Occupational Safety and Health Act of 1970, Pub. L. No. 91-596, 84 Stat. 1590 (1970).

[10]. U.S. Census Bureau, Annual Business Survey: 2022 (Data Year 2021), National Center for Science and Engineering Statistics, NSF 24-303 (Alexandria, VA: National Science Foundation, 2024), https://ncses.nsf.gov/surveys/annual-business-survey/2022.

[11]. Ibid.

[12]. Google Patents, accessed September 2025, https://patents.google.com. This chart uses Cooperative Patent Classification (CPC) codes focused on different groupings of research relevant to workplace technology to measure the approximate total amount of patent publications between 2018 and 2024. G06Q 10/0639 refers to “Performance analysis of employees; Performance analysis of enterprise or organisation operations;” G06T 7/70 refers to “Determining position or orientation of objects or cameras in image analysis” where G06Q 10/0639 is correlated with algorithmic management technologies and G06T 7/70 is correlated with technology that uses image analysis monitoring for workplace safety and productivity tracking.

[13]. Google Patents, accessed September 2025, https://patents.google.com. This chart uses CPC codes. A61B 5/1455 refers to “using optical sensors, e.g. spectral photometrical oximeters for measuring blood gases [with] sensors specially adapted…for cerebral tissue, the eye fundus, by fluorescence, to extracorporeal circuits, by polarization;” and B25J 19/00 refers to “Accessories fitted to manipulators, e.g. for monitoring, for viewing; Safety devices combined with or specially adapted for use in connection with manipulators;” where A61B 5/1455 is correlated with sensors that can detect stress or alertness levels in workers and B25J 19/00 is correlated with exoskeletons and assistive devices for manual labor.

[14]. U.S. Census Bureau, Annual Business Survey: 2022 (Data Year 2021), National Center for Science and Engineering Statistics.

[15]. International Labour Organization (ILO), “Statistics on Safety and Health at Work” (non-fatal occupational injuries per 100,000 workers; median calculated by author based on 98 countries with available data), accessed September 2025, https://www.ilo.org/safework/statistics-and-databases/lang--en/index.htm.

[16]. ILO, Safety And Health at the Heart of the Future of Work (ILO, 2019), https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@dgreports/@dcomm/documents/publication/wcms_686645.pdf.

[17]. ILO, “Statistics on Safety and Health at Work.”

[18]. Occupational Safety and Health Administration (OSHA), “Severe Injury Reports” (machinery-related workplace injuries, January 2015–December 2023), “source of injury or illness” filtered by “machinery,” accessed September 2025, https://www.osha.gov/severe-injury-reports; Occupational Injury and Illness Classification System (OIICS) Event Tree, Centers for Disease Control and Prevention, https://wwwn.cdc.gov/wisards/oiics/Trees/MultiTree.aspx?TreeType=Event.

[19]. Ibid.

[20]. Anand Krishnan et al., “Data-driven ergonomic risk assessment of complex hand-intensive manufacturing processes,” Communications Engineering 4 (2025): 45. DOI: 10.1038/s44172-025-00382-w.

[21]. Vishal Patel et al., “Trends in Workplace Wearable Technologies and Connected-Worker Solutions for Next-Generation Occupational Safety, Health, and Productivity,” Advanced Intelligent Systems 4 (2021): 2100099. DOI: 10.1002/aisy.202100099.

[22]. Ibid.

[23]. Beibei Feng et al., “Prevalence and risk factors of self-reported wrist and hand symptoms and clinically confirmed carpal tunnel syndrome among office workers in China: a cross-sectional study,” BMC Public Health 21 (2021): 57. DOI: 10.1186/s12889-020-10137-1.

[24]. BLS, Employer-Reported Workplace Injuries and Illnesses, 2023. Table 1: Incidence Rates of Nonfatal Occupational Injuries and Illnesses by Industry and Case Types, 2023, accessed September 2025, https://www.bls.gov/iif/nonfatal-injuries-and-illnesses-tables/table-1-injury-and-illness-rates-by-industry-2023-national.htm; BLS, Census of Fatal Occupational Injuries, 2023, Table A-1: Fatal Occupational Injuries by Industry and Event or Exposure, 2023, accessed September 2025, https://www.bls.gov/iif/fatal-injuries-tables/fatal-occupational-injuries-table-a-1-2023.htm; BLS, Employment by Major Industry Sector, 2024. Table 2.1: Employment by Major Industry Sector, accessed September 2025, https://www.bls.gov/emp/tables/employment-by-major-industry-sector.htm.

[25]. Ibid.

[26]. Chiang Liang Kok et al., “Energy-, Cost-, and Resource-Efficient IoT Hazard Detection System with Adaptive Monitoring,” Sensors 25, no. 6 (2025): 1761. DOI: 10.3390/s25061761.

[27]. Siemens AG, “Plant and process safety with Safety Integrated” (industry report, Siemens AG, 2022), https://assets.new.siemens.com/siemens/assets/api/uuid:17f1443e-76db-4060-9e01-f5ccf4fdf5bb/plant-and-process-safety-with-safety-integrated.pdf.

[28]. Krishnan et al., “Data-driven ergonomic risk assessment of complex hand-intensive manufacturing processes.”

[29]. “MSD Solutions Commons,” National Safety Council (NSC), accessed September 2025, https://www.nsc.org/workplace/safety-topics/msd/msd-solutions-commons; “Effective Use of Custom Pick Planning Software” (industry report, Amazon, 2025), https://www.nsc.org/getmedia/61757b92-3c0f-4070-a641-9021a193e4b2/msd-commons-amazon-case-study.pdf; “Implementation of Wearable Sensors for Risk Assessments and Real Time Feedback” (industry report, Pacific Gas & Electric Company, 2025), https://www.nsc.org/getmedia/7c438300-720c-4689-8507-5f6b46c2ed34/msd-commons-pge-casestudy.pdf.

[30]. Yi Niu, Yunxiao Fan, and Xing Ju, “Critical review on data-driven approaches for learning from accidents: Comparative analysis and future research,” Safety Science 171 (March 2024): 106381. DOI: 10.1016/j.ssci.2023.106381.

[31]. “Societal Costs,” NSC, accessed September 2025, https://injuryfacts.nsc.org/all-injuries/costs/societal-costs/data-details/.

[32]. National Safety Council, "Work Injury Costs," accessed September 2025, https://injuryfacts.nsc.org/work/costs/work-injury-costs/.

[33]. Ibid.

[34]. “Driver Distraction and Fatigue Detection and Warning System, Phase II,” Federal Motor Carrier Safety Administration (FMCSA), accessed September 2025, https://www.fmcsa.dot.gov/safety/research-and-analysis/driver-distraction-and-fatigue-detection-and-warning-system-phase-ii.

[35]. Jamaliatul Badriyah et al., “An Optimization Model for the Nurse Scheduling Problem Considering Workload Variance,” Jurnal Derivat Vol. 11, No. 3 (2024). DOI: 10.31316/j.derivat.v11i3.6899; Aristeidis Mystakidis et al., “Optimizing Nurse Rostering: A Case Study Using Integer Programming to Enhance Operational Efficiency and Care Quality,” Healthcare (Basel) 12 (2024):2545. DOI: 10.3390/healthcare12242545.

[36]. Martin Golz et al., “Evaluation of fatigue monitoring technologies.” Somnologie - Schlafforschung und Schlafmedizin 14 (2010): 187–199. DOI: 10.1007/s11818-010-0482-9.

[37]. Yekta Said Can, Bert Arnrich, and Cem Ersoy, “Stress detection in daily life scenarios using smart phones and wearable sensors: A survey,” Journal of Biomedical Informatics Vol. 92 (2019): 103139. DOI: 10.1016/j.jbi.2019.103139; Jacqueline Wijsman et al., “Towards mental stress detection using wearable physiological sensors,” Annual International Conference of the IEEE Engineering in Medicine and Biology Society (2011): 1798–1801. DOI: 10.1109/IEMBS.2011.6090512.

[38]. Matt Scherer and Lydia X. Z. Brown, “Report – Warning: Bossware May Be Hazardous to Your Health” (Center for Democracy & Technology (CDT), July 2021), https://cdt.org/insights/report-warning-bossware-may-be-hazardous-to-your-health/; “Workplace Privacy,” Electronic Privacy Information Center (EPIC), accessed September 2025, https://epic.org/issues/data-protection/workplace-privacy/.

[39]. Rifaat Abdalla, “Transforming the Industry: Digitalization and Automation in Oil and Gas Wells,” in Advances in Oil and Gas Well Engineering, edited by Yongcun Feng (London: IntechOpen, 2024), 45–68. DOI: 10.5772/intechopen.112512; Loreto Codoceo-Contreras, Nikodem Rybak, and Maureen Hassall, “Exploring the impacts of automation in the mining industry: A systematic review using natural language processing,” Mining Technology 3, 133 (2024): 191-213. DOI: 10.1177/25726668241270486; Bureau of Labor Statistics (BLS), Productivity (Manufacturing and Mining Labor Productivity; accessed September 2025), https://www.bls.gov/productivity/highlights/manufacturing-mining-labor-productivity.htm; Minyoung Suh, “Automated Cutting & Sewing For Industry 4.0,” Textile World, February 13, 2024, https://www.textileworld.com/textile-world/knitting-apparel/2024/02/automated-cutting-sewing-for-industry-4-0/.

[40]. Ibid.

[41]. “Applications of robotics in the oil and gas industry,” Offshore Technology Focus, accessed September 2025, https://offshore.nridigital.com/offshore_technology_focus_sep23/case-studies-robotics-oil-gas-industry; Putri Azmira R Azmi, Marina Yusoff, and Mohamad Taufik Mohd Sallehud-din, “A Review of Predictive Analytics Models in the Oil and Gas Industries,” Sensors Vol. 24, no. 12 (2024): 4013. DOI: 10.3390/s24124013; Hazem Ramzey, Mahmoud Badawy, and Adel A. Elbaset, “Crude oil industry remote monitoring and management based on Industrial Internet of things and edge computing integration: A comprehensive survey,” Results in Engineering Vol. 24 (2024): 103034. DOI: 10.1016/j.rineng.2024.103034.

[42]. Pavithra Salanke et al, “Textile 4.0. Digital Revolution in textile industry,” Asian Textile Journal 31 (2022): 58–61, https://www.researchgate.net/publication/367462878_Textile_40_Digital_Revolution_in_textile_industry.

[43]. “International Grocery Retailer Improves Worker Well-Being, Boosts Productivity with Exosuits” (industry report, HeroWear, 2024), https://herowearexo.com/wp-content/uploads/HeroWear-Case_Study-Productivity-Worker-Well-Being-2024.pdf.

[44]. Matt Leonard, “Pick speed improves when augmented reality replaces paper: study,” Supply Chain Dive, January 26, 2021, https://www.supplychaindive.com/news/picker-augmented-reality-speed-warehouse-ar-china/593989.

[45]. “DHL successfully tests augmented reality application in warehouse,” DHL, accessed September 2025, https://www.dhl.com/global-en/delivered/innovation/dhl-successfully-tests-augmented-reality-application-in-warehouse.

[46]. GAO, “Science & Tech Spotlight: Wearable Technologies in the Workplace” (Washington DC: GAO, March 2024), https://www.gao.gov/assets/d24107303.pdf.

[47]. Erik Brynjolfsson, Danielle Li, and Lindsey R. Raymond, “Generative AI at Work” (working paper, No. 31161, National Bureau of Economic Research, 2023), https://www.nber.org/system/files/working_papers/w31161/w31161.pdf.

[48]. “The economic potential of generative AI: The next productivity frontier” (McKinsey & Company, June 2023), https://www.mckinsey.com/capabilities/mckinsey-digital/our-insights/the-economic-potential-of-generative-ai-the-next-productivity-frontier; Hyoung Seok Kang et al., “Smart manufacturing: Past research, present findings, and future directions,” International Journal of Precision Engineering and Manufacturing-Green Technology Vol. 3 (2016): 111–128. DOI: 10.1007/s40684-016-0015-5; A M Donoghue, “Occupational health hazards in mining: an overview,” Occupational Medicine Vol. 54, 5 (2004): 283-9. DOI: 10.1093/occmed/kqh072.

[49]. Elizabeth Marsh, Elvira Perez Vallejos, and Alexa Spence, “The digital workplace and its dark side: An integrative review,” Computers in Human Behavior Vol. 128 (2022): 107118. DOI: 10.1016/j.chb.2021.107118.