A Time to Act: Policies to Strengthen the US Robotics Industry

Robots are the future. It is time for Congress and the administration to take a number of straightforward and affordable steps to boost U.S. robotics innovation and adoption.

KEY TAKEAWAYS

Key Takeaways

Contents

Adoption and Production: Where the United States Stands 4

Other Nations’ Robotics Strategies and Policies 9

Introduction

Robotics is the Rodney Dangerfield of technologies. Compared with artificial intelligence (AI), quantum, blockchain, and all the other “cool kids,” it gets no respect. But that, thankfully, is changing. An array of technologies are improving and coming together to enable robotics to be a key “general purpose technology” for the next technology long wave.[1]

If the United States is to move beyond its anemic levels of productivity growth, applying robotics to a wide assortment of physical tasks (not just in manufacturing but virtually every industry that involves assembling or moving “things,” including people) will be critical. Robotics is also now a key dual-use technology with important applications in both defense and commercial applications. Letting China win the robotics competition would be highly problematic, and as the Information Technology and Innovation Foundation (ITIF) has shown, the People’s Republic of China (PRC) is well on its way to global dominance in robotics.[2]

As such, national robotics policies should focus on both supporting the development and global competitiveness of the U.S. robotics industry as well as the widespread adoption of robots across the U.S. economy.

Other nations, particularly China, have developed and implemented robust national robotics strategies. The United States has not. The result has been extremely low rates of robotics adoption and a lagging national robotics industry. Congress needs to take action to change that. To that end, it has already taken a useful step with the implementation of first-year expensing for equipment investment (in the recent “Big Beautiful Bill”), which will lower the after-tax costs of robotics adoption. Ideally, Congress would pass a CHIPS Act-style bill with large ambitions and robust funding for robotics. But this report assumes that is for another day, given the fiscal challenges facing the federal government. Rather, it lays out a legislative and administrative policy agenda for robotics that has a low “price tag.” However, first, the report discusses why robotics is important, how the United States is performing, and what other nations are doing to support robotics.

National robotics policies should focus on both supporting the development and global competitiveness of the U.S. robotics industry as well as the widespread adoption of robots across the U.S. economy.

Note that this report does not address concerns about structural unemployment from robust robotics adoption. ITIF has done that in many other publications in the past.[3] Suffice it to say that this is not a valid concern. The scholarly literature, historical evidence, and logic show that while robotics applications will lead to some job loss (and as described herein, Congress needs to improve programs for dislocated workers), it will not lead to higher levels of unemployment. Other jobs will be created. What it will do is boost U.S. per-capita living standards by allowing the economy to produce more with the same number of workers. It will also enable the United States to more effectively compete in global markets because production costs will be lower.

Why Robotics Matters

While there is no hard and fast definition of robotics, the term generally refers to physical machines that can be programmed to perform a variety of different tasks, with some level of interaction with the environment and limited or no input from an operator. Some will argue that autonomous systems (e.g., drones or autonomous vehicles) are robots. For the purpose of this report, we will focus on more traditional robotics.

Robotics technology has the potential to be the most important technology of the next half century. Improving productivity in many functions and industries that involve moving or transforming physical things will depend on much better and cheaper robotics technology. To be sure, robots are already driving productivity. But we have barely scratched the surface of their potential because of limitations in functionality and costs. There is no reason why robots could not pick up litter or clean streets and parks. They could prepare and deliver food in restaurants, provide room service in hotels, and clean buildings. Robots could operate forklifts in warehouses, stock shelves in stores, lay bricks, dig trenches, and, as they do in China, construct roads. They could pick vegetables, fruit, and other crops that currently require manual labor. They could reduce the cost of caring for the elderly, both at home and in assisted-living facilities.[4] They can improve mining and manufacturing productivity, particularly in assembly and transport functions.

Yet, as MIT roboticist Rodney Brooks wrote, “Having ideas is easy. Turning them into reality is hard. Turning them into being deployed at scale is even harder.” That is why a national robotics strategy is so important.

Rather than think about robotics as discrete things—which they are—they are also in some cases platforms. The smartphone, enabled by Moore’s law and 4G connectivity, sparked an enormous number of applications, many or even most of which were not even thought of before 2006. Robotics, while getting better with both hardware and software (including AI) improvements, is likely to be the same, with our imagination as one key limit.

The cost of implementing certain digital manufacturing technologies has decreased in recent years. As Mike Coast and Bob Lyscas of the Michigan Manufacturing Technology Center (Michigan’s MEP) explained:

In some areas like smart sensors or robotics, the cost has been reduced by as much as 80 percent even over the past three years; what was costing in the area of $750,000 three years ago might be closer to $100,000 today. That lower cost is accelerating return on investment (ROI). For a 150–200 person-size company, we’re seeing ROI within 1.2–2 years and on the larger size firms (200–500 employees) we’re seeing good ROI data in the two to five-year timeframe.”[5]

Still, costs need to fall further, and ease of use, flexibility, and quality need to get better.

Yet, as MIT roboticist Rodney Brooks wrote, “Having ideas is easy. Turning them into reality is hard. Turning them into being deployed at scale is even harder.”[6] That is why having a national robotics strategy is so important. The United States has a critical interest in accelerating robotics development and ensuring adequate robotics production.

Adoption and Production: Where the United States Stands

Like any production technology, both the manufacturing of robotics and its adoption are important. The United States lags behind on both.

U.S. Robot Adoption

Robots development and adoption are key to boosting productivity and living standards because they increase firms’ efficiency. As a study by Mayer finds, greater robot density in manufacturing is linked to higher output and, in turn, stronger gross domestic product (GDP) and better living standards.[7]

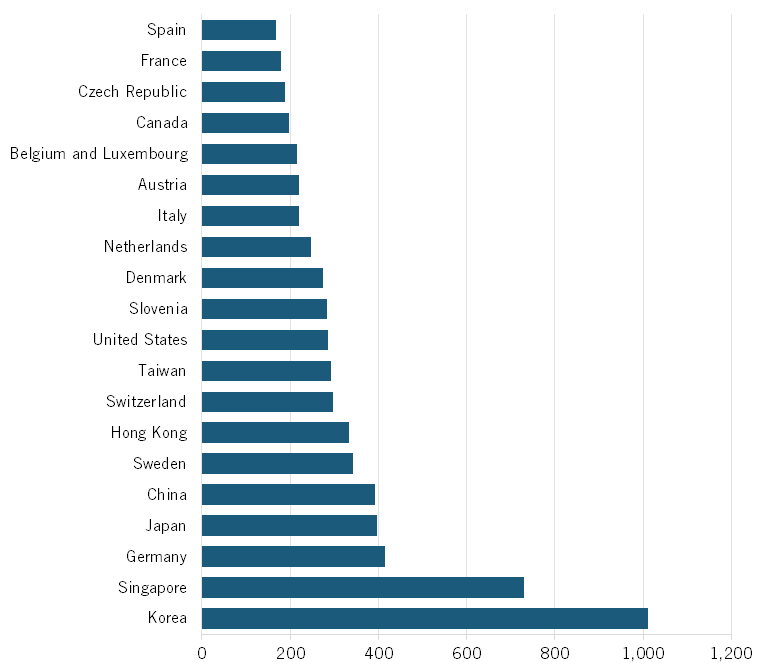

However, despite this, the United States has failed to lead in the adoption and development of robots when compared with other nations. Indeed, according to data from the International Federation of Robotics (IFR), the United States was the ninth largest adopter of industrial robots in the world with 285 robots per 10,000 manufacturing workers in 2022—down from seventh place in 2017.[8] (See figure 1.) In comparison, South Korea ranked as the world’s largest adopter of industrial robots with 3.5 times more robots per 10,000 manufacturing workers—1,012 robots—than the United States.[9] Similarly surpassing the United States, Germany had 415 robots, Japan had 397 robots, and China had 392 robots per 10,000 workers.[10]

Figure 1: Industrial robots per 10,000 manufacturing workers, 2022[11]

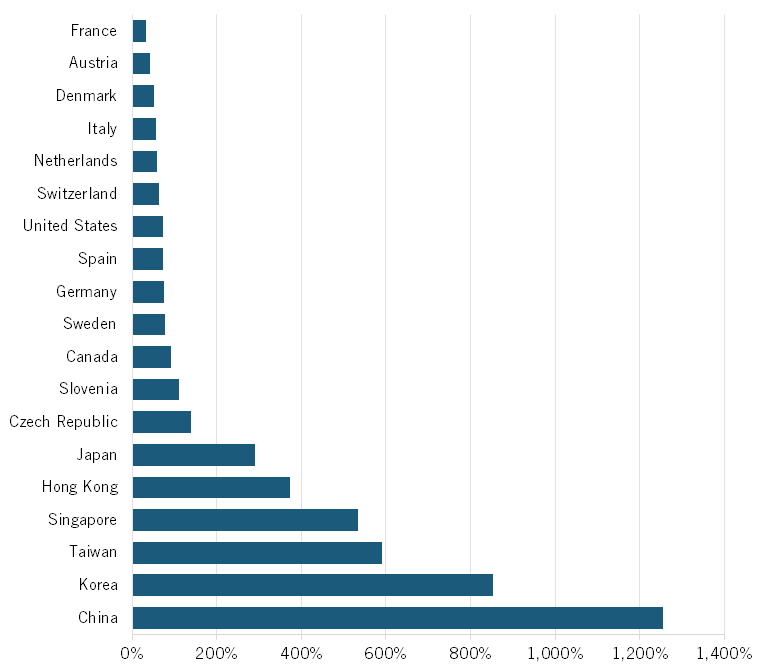

Moreover, controlling for wage levels, the United States performed even worse in robot adoption in 2022. When ITIF compared expected robot adoption rates with actual rates, the United States ranked 13th with just 70 percent of expected robot adoption given its manufacturing wages.[12] (See figure 2.) Meanwhile, at the top were East Asian nations with China adopting 12.5 times more robots than expected, South Korea adopting 8.5 times more, Taiwan 5.9 times more, and Singapore with 5.3 times more.[13]

Figure 2: Actual robot adoption rate as a share of expected robot adoption rate, 2022[14]

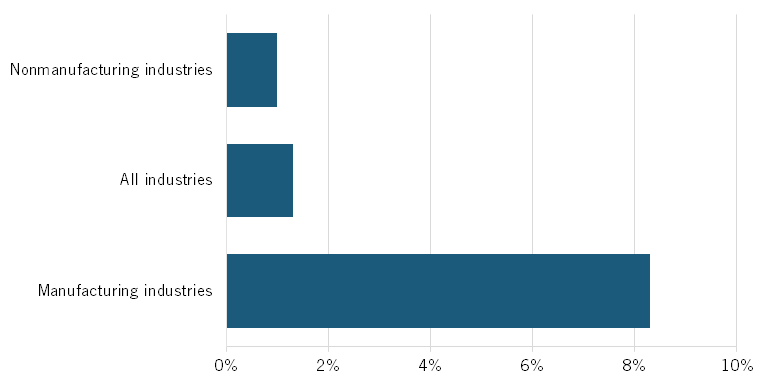

Only 8.3 percent of U.S. manufacturing industries’ firms, which benefit most from using robots, have actually incorporated robots.

The fact that the United States lags behind other nations in robot adoption and development is not surprising. While other nations have established national goals and strategies to support robotics innovation and adoption, the United States has established policies that tend to harm robotics adoption and innovation. For instance, an ITIF report finds that while some nations have proactive tax policies to incentivize robotics adoption, the United States offers less-generous tax treatment of capital expenditures, thereby disincentivizing investments in robotics.[15] These policies are partly because the Americans tend to be more concerned over robots taking over jobs, despite multiple studies finding the contrary. As a study by Lee and Sabanovic finds, cultural attitudes play a role in a nation’s robot adoption rate.[16] Corroborating this, an ITIF study also concludes that countries’ wage-adjusted industrial robot adoption rates are modestly positively correlated with the degrees to which countries’ residents believe more emphasis should be placed on the technology in the future.[17]

As a result, the United States’ lack of support for robotics adoption and development has led to low robot adoption rates across industries. According to the National Science Foundation’s (NSF’s) Annual Business Survey, only 1.3 percent of firms in all industries have used robots as part of their processes or methods in the production of goods and services.[18] Meanwhile, only 1 percent of nonmanufacturing industries’ firms have incorporated robots.[19] Although higher, only 8.3 percent of U.S. manufacturing industries’ firms, which benefit most from using robots, have actually incorporated robots.[20] (See figure 3.) Fortunately, the rates of usage are slightly higher for key advanced manufacturing industries where higher output is most important, which could lead to higher global market shares. These industries include computer and electronic products (usage rate: 12.1 percent); electrical equipment, appliances, and components (usage rate: 9.1 percent); and aerospace products and parts (14.2 percent).[21] Nevertheless, U.S. industries’ robot usage rates are still quite low, leading to a low overall robotics adoption rate in the United States.

Figure 3: Share of firms using robotics as part of their processes or methods[22]

U.S. Robot Production

Despite pioneering robotics, the United States does not lead the world in producing them, raising serious alarm. As with so many advanced technologies, the United States remains strong in research and invention but weak in manufacturing. While U.S. labs continue to deliver cutting-edge robotics breakthroughs, the actual production of industrial robots is now dominated by foreign competitors. Japan, for instance, accounted for 46 percent of global robotics output and 36 percent of exports in 2022.[23] The United States, despite its much larger economy, accounted for just 5.4 percent of global robotics exports.[24] That means Japan’s robot export intensity is roughly 20 times higher than that of the United States.[25] As such, the message is clear: America’s robotics know-how is not being matched by an ability to produce at scale.

This is because the broader U.S. industrial ecosystem that’s needed to support large-scale robotics production remains underdeveloped. The United States does not have a single major firm mass-producing industrial robots. In other words, the United States has no domestic foundries making them.[26] As a result, Japan, Germany, and China are the main providers of critical robot components such as servo motors, speed reducers, and precision sensors.[27] Despite the United States hosting leading foreign robotics firms such as ABB and Fanuc, these firms do most of their advanced manufacturing elsewhere.[28] As a result, the United States ran a $1.26 billion trade deficit in robotics in 2022, exporting less than one-third the value it imported.[29] Moreover, even with its poor production compared with other nations, the United States’ flagship public-private accelerator, the ARM Institute, operates with just $30 million while China is investing $138 billion to expand its AI and robotics manufacturing base.[30]

The United States does not have a single major firm mass-producing industrial robots.

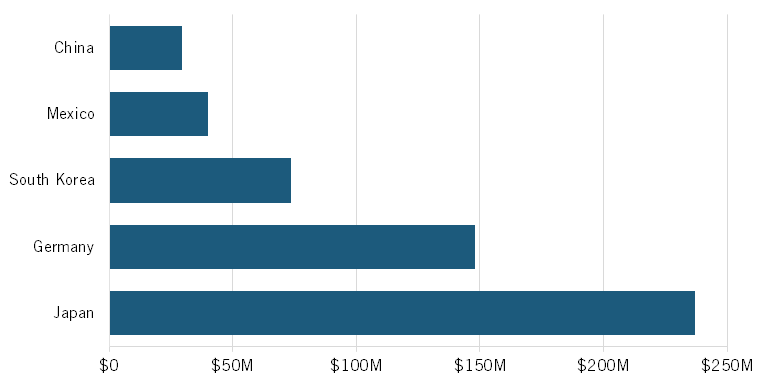

More recent data from the Observatory of Economic Complexity also shows that the United States continues to depend on other nations for robots. Indeed, the United States exported only $169 million in industrial robots while importing more than 4 times that amount at $707 million in 2024.[31] Of the $707 million in imports, $237 million came from Japan, $148 million from Germany, $73.7 million from South Korea, $39.9 million from Mexico, and $29.7 million from China.[32] (See figure 4.)

Figure 4: U.S. imports of industrial robots by country in 2024[33]

That said, the United States does have some robotics companies. Massachusetts-based Teradyne Robotics is a global leader in advanced robotics through its ownership of Universal Robots, the pioneer and market leader in collaborative robots, and Mobile Industrial Robots, a pioneer and top player in autonomous mobile robots.[34] This American leadership in two of the fastest-growing robotics segments is a significant asset to the nation’s robotics ecosystem, and Teradyne recently announced plans to open a robotics manufacturing and service center in the United States.[35] Productive Robotics, a California-based company, manufactures 95 percent of its parts domestically and produces multi-axis collaborative robots that help automate machining processes.[36] Ingersoll Machine Tools in Illinois developed the Master Print Robotic, which combines 3D printing and CNC milling in a single machine. The United States is also home to a vibrant ecosystem of robotics start-ups, thanks in part to its leadership in software.[37] And companies such as Rockwell Automation are global leaders in the services side of the robotics industry. These examples show that the United States still has the talent and capability to compete. But without a broader strategy to translate innovation into production, they remain exceptions, and fast followers in other nations can quickly replicate American breakthroughs and undercut U.S. firms on cost. If the United States wants to reclaim leadership in robotics, it must use policy to proactively incentivize robotics production.

Other Nations’ Robotics Strategies and Policies

As robotics and automation have become a critical technology among advanced nations, many countries have established comprehensive national strategies to support innovation and adoption in the industry, while others have adopted an ala carte approach to robotics policy, implementing research and development (R&D) incentives and workforce training programs in robotics. This section reviews the various robotics strategies employed to drive growth in both the supply and demand of the robotics industry.

National Strategies

Leading nations have increasingly deployed national robotics strategies as a comprehensive approach to catalyze the innovation and growth of robotics sectors. These strategies often involve a range of incentives, subsidies, and other programs designed to not only increase investment in robotics R&D but also incentivize adoption, a key challenge for many nations seeking to automate. Although complex to implement, a national strategy encompassing most or all elements of robotics growth is the most effective way to build a nation of robotics innovation.

In 2014, Japan was one of the first nations to recognize the power of automation and robotics, establishing its goal to realize a “new industrial revolution driven by robotics.”[38] Shortly thereafter, the Japanese government announced its “New Robot Strategy,” an initiative from 2016 to 2020 focused on the adoption of robotics in key, low-productivity sectors, including agriculture, healthcare, and infrastructure.[39]

In 2020, Japan launched the Moonshot Research and Development Program, which, although not solely focused on robotics development, places emphasis on the development of AI and autonomous learning robots. The program is investing $440 million in 10 technology goals through 2050, including AI robotics. Japan’s desire for greater automation stems from a necessity perhaps greater than that of any other country. Its rapidly aging population has placed pressure on its economy, leading to a shrinking workforce and a greater need for employees in the service and healthcare sectors. Thus far, Japan’s strategies have been successful. In 2024, it was the number one industrial robot manufacturer in the world, and had the fifth greatest robot density, with 419 robotic units per 10,000 workers installed.[40]

South Korea will invest $2.2 billion in service and manufacturing robotics through 2028, with the aim of deploying 1 million robots globally by 2030.

Similar to Japan, South Korea has enacted several iterations of its national robotics strategies, all of which have been successful in propelling Korea to the top of global robotics leadership. Beginning with its Intelligent Robots Development and Distribution Promotion Act of 2008, South Korea is currently implementing its 4th Basic Plan on Intelligent Robots, which was launched in January 2024 and will run through 2028. The plan is investing $2.2 billion in the robotics industry, specifically supporting the development of robotics for the manufacturing and services sectors. The plan aims to establish the K-Robot economy, expanding the industry’s global reach and deploying 1 million robots by 2030.[41] South Korea was the world’s number one adopter of industrial robots in 2024, with a robot density of 1,012 robots per 10,000 employees.[42]

In Europe, the campaign for robotics innovation is underway at both the continental and national levels. Horizon Europe, the European Union’s innovation framework, has emphasized the need to develop Europe’s robotics industry. But unlike other countries, it has stressed the need for robots to be complements to humans, not replacements. The EU has allocated nearly $100 billion for this initiative through 2027, with funding going to several key focus areas, including robotics in healthcare, climate change technology, and agriculture. At the same time, the European Commission has provided $183 million through the end of 2025 for a robotics-related work program.[43] Despite these initiatives, the EU’s robot density is rather low, at about 219 robots per 10,000 workers.[44]

Within the EU, several countries have developed their own national robotics strategies. Germany, France, and the Netherlands have all implemented individual national strategies with focuses tailored to their respective countries. Germany and the Netherlands are focusing their investments on service robot innovation for logistics and manufacturing, while France’s “Robolution” initiative concentrates on research more broadly, with a goal of establishing a network of robotics research centers.[45]

When it comes to robotics strategies, no nation has implemented one as comprehensive as China’s.

Other nations, such as India, Singapore, and Australia, have focused their national robotics strategies around select industries in which they have a comparative advantage. Singapore has launched its National Robotics Programme, focusing on incentivizing robotics R&D in three key sectors: healthcare, construction and infrastructure, and environmental services.[46] Similarly, India’s National Strategy for Robotics emphasizes leveraging robotics for economic development, with a focus on the agriculture, healthcare, and manufacturing sectors.[47] Australia’s National Robotics Strategy aims to increase automation, not only in traditional industries such as agriculture and manufacturing but also in natural resource-intensive sectors, including mining and marine industries.[48]

However, when it comes to robotics strategies, no nation has implemented one as comprehensive as China’s. Since 2014, China, under the leadership of President Xi Jinping, has been seeking a so-called “robot revolution” by implementing multiple robotics strategies and outlining 11 key areas where it aims for more robotics innovation and adoption. These include healthcare, education, and energy.[49] China is currently on its 14th Five-Year Plan for Robot Industry Development, which complements its overall five-year development strategy, “Made in China 2025.” Within this strategy are the creation of regional innovation hubs and research institutes focused on robotics, as well as national, provincial, and local subsidies for research investment and adoption. Additionally, there are foreign direct investment incentives, such as attractive tax policies and state-backed venture capital funds, and support for the acquisition of already established advanced robotics firms in other countries.[50]

This moonshot approach to robot development has been successful thus far, with China’s robot density having doubled over the past four years, increasing to 470 units per 10,000 workers, ranking it third globally. If China continues at its current growth rate, it will surpass South Korea for the world’s greatest robot density by 2026.[51]

Tax Credits, Subsidies, and Grants

Some of the most fundamental elements of a national robotics strategy include financial incentives for firms conducting R&D and manufacturing robots. These incentives often take the form of tax breaks, subsidies, and research grants awarded to firms that are recognized for conducting innovative work in the field. Several countries offer incentives such as these.

In Germany, the largest robotics market in Europe, robotics firms benefit from their position within the EU, as firms are eligible for research funding from the German and EU governments. The EU has allocated $100 million to research funding in key technology areas, while the German government is offering cash grants for R&D support totaling €70 million, or $81.6 million, through 2026.[52] Additionally, Germany’s Research Allowance Act provides a 25 percent R&D tax credit to firms for up to €500,000 per firm for R&D investments. This R&D tax credit is not specific to robotics research, but robotics firms qualify.[53]

R&D tax credits were the most widely used and economically significant policy device to support research activities in the Organization for Economic Cooperation and Development (OECD) in 2024. In the OECD, 34 out of 38 nations implemented some form of an R&D tax credit, reimbursing researchers with a portion of their research expenses after the fact. Portugal, Iceland, and the United Kingdom provided the greatest tax relief for R&D as a percentage of GDP.

Several countries, including the United Kingdom, the Netherlands, Switzerland, and the UAE, provide additional subsidies for R&D explicitly conducted in the robotics industry. The United Kingdom, for example, has pledged £93 million, or approximately $125 million, to robotics R&D through its Industrial Strategy initiative.[54]

The Chinese national government has established a state-owned venture capital fund for robotics, AI, and other critical technologies, with the goal of $138 billion in capital by 2045. Provincial governments have also invested millions of dollars in robotics.

Rather than a specific national robotics strategy, Australia has a national Industry Growth Program designed to boost innovative technology industries, including robotics. This strategy also utilizes an R&D tax credit to incentivize investment in robotics, which ranges from 8.5 percent to 18.5 percent, depending on company size and R&D intensity.[55] Additionally, Australia has begun implementing a series of grants for small and medium-sized enterprises (SMEs) working in one or more of the seven government-identified industry priority areas (including robotics). Grants can reach up to $5 million.[56]

Unsurprisingly, the financial incentives offered by the Chinese government for robotics firms are substantial. The national government has established a state-owned venture capital fund for robotics, AI, and other companies operating in critical technologies, intending to raise $138 billion in capital by 2045. Provincial and local governments have also made a point to invest heavily in state robotics capabilities. Beijing announced a $1.4 billion robotics fund to promote the development of robotics technology, while Shenzhen announced a $630 million policy package to advance AI and robotics innovation, with individual subsidies covering up to 60 percent of a business’s total costs.[57] However, it is possible these values are inflated, as provincial governments are likely to curry favor with the national government based on the value of the incentives provided.[58] Regardless, even if exaggerated, these values are significant investments in Chinese robotics adoption.

Research Institutes

Research institutes are organizations focused on conducting specialized research, often in critical technology areas, including robotics. Institutes, especially those funded publicly, are key components in developing an innovation ecosystem, as they often conduct research deemed too risky for businesses and too specialized for universities, thereby filling the gap between the amount of market R&D investment and the socially optimal amount of R&D. Robotics research institutes are key to translating basic research into marketable solutions with an economic impact.

Several nations have plans within their national robotics strategies to establish or expand networks of research institutions. India’s national strategy calls for a network of Centers of Excellences (CoEs) to be developed. These centers will undertake both foundational and applied research. For India, robotics represents a path toward economic growth and development; however, investment in the technology by the private sector is low due to the high costs of capital and training employees. The CoEs will benefit the Indian economy in two ways. For one, they will support the training of future robotics experts, thereby increasing the supply of trained professionals in the field and decreasing the future cost of hiring and training workers. Additionally, they will partner with private sector firms to conduct applied robotics research, thereby reducing the R&D costs for these companies.[59]

In the UAE, Dubai Future Labs are publicly funded research labs that, like those in India, conduct research on the “pain points” of the robotics industry that are otherwise untouched by private firms, and work to turn basic research into applied research for product development. The Future Labs have been used to develop unmanned aerial vehicles for last-mile delivery and beyond-visual-line-of-sight drones. They are focusing on accelerating R&D in five areas, including robotics in production and manufacturing, tourism, mobility and logistics, extreme environments, and healthcare.[60]

In addition, the Labs serve as a teaching facility and a working space for private researchers, who can utilize Dubai Future Lab’s facilities to test newly developed technologies using its state-of-the-art equipment. The Labs also act as teaching facilities with workforce training programs. Internships, fellowships, and Ph.D. programs are offered to young graduates, enabling them to work in labs under the guidance of experts in the field of robotics.[61]

The Chinese government has also established research institutes and innovation hubs for robotics, following the model of the American system, Manufacturing USA. Like Manufacturing USA, China has established several public-private research institutes in critical technologies, including one focused on robotics. However, unlike the American system, China has centered all activities related to a specific technology, such as research institutes, companies, universities, and other research activities, in one location. For robotics, one of these locations is Dongguan Robot City. There, the robotics industry is a key player in the economy, and publicly funded research institutions play a central role in the economy.[62]

Germany has also developed a robotics research institute similar to those in the UAE and India, while Japan and Saudi Arabia have each established public-private robotics partnerships, facilitating the transfer of knowledge and skills between establishments. One study finds the Japanese program to be highly effective in spurring robotics development.[63]

Workforce Training

Developing a strong robotics economy involves not just investment in R&D and partnerships with innovative firms, but also educated and capable workers. This makes adequate robotics education programs not a want, but a need. Several countries have established robotics training programs for students in schools and universities, as well as reskilling programs for post-graduate professionals.

Saudi Arabia launched the Saudi Vision 2030 initiative in 2016, a plan aimed at transitioning the country away from its reliance on energy and oil and developing expertise in other areas of Industry 4.0, including robotics. Within this initiative, Saudi Arabia is emphasizing the importance of robotics education, particularly at a young age. The King Abdulaziz City for Science and Technology (KACST), an autonomous government organization dedicated to promoting science and technology, has introduced STEM education programs into the country’s educational curricula for students. Along with teaching students the principles of robotics, students are provided with robotics equipment and resources and offered classes in programming and engineering. The success of these programs is evident in the growing popularity of robotics competitions nationwide. KACST has also developed robotics training workshops and training centers to provide individuals with hands-on experience in robotics technology.[64]

Germany and Mexico, both manufacturing powerhouses, have seized the opportunity to leverage automation in factories, particularly in the automotive industry.

In Brazil, the focus has been on bringing robots to students and working adults, thereby increasing exposure and interest in the field. Universal Robots, a collaborative robot (cobot) manufacturer, has sold over 200 cobots to Brazil’s National Industrial Training Service, reaching more than 2 million students and professionals. Additionally, Brazil’s Social Service of Industry agency has purchased over 20 cobots for 7 to 17 year-old students in the federal state of Minas Gerais, increasing early exposure to robots and STEM (science, technology, engineering, and math) fields broadly.[65]

Germany and Mexico, both manufacturing powerhouses, have seized the opportunity to leverage automation in factories, particularly in the automotive industry. This strong demand for robotics professionals has led to the development of hundreds of higher education robotics programs in both nations, with over 300 each.[66] Mexico also now offers federal scholarships to students studying in critical technology fields, including robotics.

Adoption Incentives

For many countries, including the United States, the reluctance of firms to adopt robotics and automation into their operating procedures is a significant hurdle to overcome. Consequently, it has become commonplace for governments to offer incentives to firms that adopt automation technology. Some nations have created incentives or programs specifically to encourage robotics adoption, while others have roped robotics in with other productivity-enhancing equipment, such as machinery and software.

In Singapore, which already has one of the highest robot densities in the world, the government invested $60 million in 2024 alone to promote the adoption of robotics. The incentives offered through the program include the first-year full expensing of any prescribed computer or automation equipment, including robots, as well as the launch of Singapore’s RoboCluster initiative.[67] RoboCluster will partner robotics firms with industries that are seen to benefit most from automation, such as facilities management, and offer forums and workshops to foster trust between the public and robots, encouraging further adoption of robotics.[68]

South Korea, which has the highest robot density in the world, has developed a range of policy tools to encourage the adoption of robotics technologies. First and foremost is the establishment of the Korea Robot Industry Promotion Agency, which is responsible for adjusting regulations and laws that restrict the expansion of the South Korean robotics industry, as well as creating and implementing incentives for adoption.[69] For example, firms investing in automation technologies are eligible to receive an additional tax deduction of up to 7 percent, depending on the size of the business.[70]

Singapore, which has one of the highest robot densities in the world, invested $60 million in 2024 to encourage the adoption of robots. This investment will finance the full expensing of automation equipment, as well as forums and workshops designed to foster trust between the public and robots.

Japan and Slovenia, meanwhile, offer accelerated depreciation to firms purchasing new equipment, including robotics, allowing firms to deduct a greater portion of an asset’s value earlier in its lifespan, incentivizing adoption.[71]

In China, provincial governments have provided significant subsidies for firms to buy robots. For example, in 2018, Guangdong Province invested approximately $135 billion for machine substitution for firms. A similar program was instituted in the Anhui province, which offered approximately $86 billion to subsidize industrial upgrading for manufacturers, including the purchase of robotics. Once again, regardless of whether these values are inflated, it remains a significant investment in robotics innovation, and one that has led China to automate at a rapid pace. Additionally, the Chinese government offers subsidies for robot purchases, with the average subsidy amounting to 17.5 percent of the equipment’s cost.[72]

In contrast, the United Kingdom, like the United States, has few incentives for the adoption of automation or robots. Both nations have less-generous tax treatment of capital expenditures and therefore exhibit lower levels of capital expenditures by manufacturers.[73] It should be unsurprising, then, that the United Kingdom has a robot density of 119 robots per 10,000 workers, a level that has been described as “very low for a Western European country.”[74]

Policy Recommendations

There are an array of things Congress and the administration can and should do to support the development and competitiveness of the U.S. robotics industry and the widespread adoption of robotics. This section lists a number of policy proposals.

However, this section does not propose significant funding and tax incentives, despite the fact that, without them, it will be more difficult to secure a strong U.S. competitive position. Ideally, Congress would pass a machinery (including robotics) tax credit. Moreover, Congress would ideally appropriate tens of billions of dollars for robotics development and production domestically.

One reason for a more focused robotics policy is that scale and learning economies matter. For every doubling of robotics adoption, robotics companies reduce costs and, just as importantly, improve quality.

Ideally, Congress and the Trump administration would announce and support a national robotics moonshot initiative. Robotics is an ideal candidate for a moonshot because successful development requires advancement in a host of related technologies, including AI, machine vision, batteries, touch sensing, speech recognition, and others. And while there are many different kinds of robots for many different kinds of applications, one application that would be an ideal candidate for a moon shot would be a household assistance robot. Such a robot could help people, including the elderly, by doing tasks such as washing dishes, doing laundry, cooking, and cleaning. A national moonshot to support research that would lead to fully functionable and reasonably affordable home robots within a decade would be a truly transformative action.

One reason for a more focused robotics policy is that scale and learning economies matter. For every doubling of robotics adoption, robotics companies reduce costs and, just as importantly, improve quality. This is particularly the case as more and more robots use AI, which relies on data. As such, without more scale for U.S. robotics producers, it is possible, and perhaps even likely, that the Chinese producers will attain an insurmountable advantage.

However, back to the real world of budget limitations and disinclinations of both parties to spend on technology development and adoption, there are still an array of policies Congress and the administration can take. These include seven major areas:

Better Data, Analytics, and Evidence

The United States government needs enhanced capabilities to better understand the robotics industry nationally and internationally.

1. The Department of Commerce should establish a federal advisory committee to advise the government on the needs of the robotics industry and how policy can build the U.S. robotics industry. Members should be predominantly from industry, with some from academia.

2. The Department of Commerce International Trade Administration should expand its focus on robotics. This is a key emerging technology, and Commerce needs stronger analytical capabilities about the industry domestically and international challenges and opportunities.

3. The U.S. Census Bureau should accelerate the timeline for releasing data from the Annual Integrated Economic Survey (AIES), which provides comprehensive data regarding national and subnational data on business activity, including data on robotics previously included as part of the Annual Survey of Manufactures and Annual Capital Expenditures Survey. The current timeline for releasing AIES data is nearly two years after collection, which makes it difficult to track changes in a rapidly evolving industry.[75]

Scientific and Engineering Research Support

4. Charge NSF with placing a higher priority on robotics research, especially research with significant industry relevance. NSF should establish one or more new Industry-University Research Partnership centers and engineering research centers for robotics.

OSTP should organize cross-agency efforts to advance AI use in edge networks, as the evolution of robotics depends on robust use of AI in robotics.

5. NSF’s Technology Innovation and Partnerships (TIP) program should select robotics for its next major technology area for support. As ITIF has written, TIP was supposed to receive significant funding under the CHIPS and Science Act to support translational and industry-relevant research in 10 strategic technology areas.[76] Lack of appropriations, compounded by recent NSF budget cuts, has meant TIP has only funded two technology areas, at only modest amounts. Congress should provide increased funding for a new TIP research initiative focused on robotics. However, no funding should be forthcoming if NSF reinstates the limitations it placed on in its prior National Robotics Initiative, which supported research only on robotics technology that complements rather than replaces workers. By limiting research funding in this way, NSF slowed the development of robotics technologies that can significantly boost productivity. In addition, it is worth noting that NSF’s National Robotics Initiative provides funding of between only $30 million and $50 million per year, a pittance when compared with what PRC governments are spending.[77]

6. The White House Office of Science and Technology Policy (OSTP) should establish a cross-cutting robotics research working group to coordinate and align all agency mission-oriented research related to robotics. This could be similar to the National Nanotechnology Initiative established in the 1990s. This is important because a variety of different agencies support research into various components of the robotics research system. And where agencies are underinvesting in robotics, such as the Department of Agriculture, they should be instructed to invest a greater share of their portfolios in robotics.

7. OSTP should organize cross-agency efforts to advance AI use in edge networks, as the evolution of robotics depends on robust use of AI in robotics.

Industry Support

8. The Department of Commerce’s Economic Development Administration should continue to support the regional innovation hub program, especially the one in Southwestern Pennsylvania focused on robotics.[78] As Commerce does this, and as the Office of Management and Budget is considering funding requests, both should keep in mind that China’s robotics hub is likely funded 20 to 40 times more generously. In addition, if possible, TIP should fund at least one regional innovation “engine” focused on robotics.

9. Congress should increase funding for NIST’s Manufacturing USA program, including expanded funding for the Advanced Robotics Manufacturing (ARM) center. ARM has completed over 120 advanced technology projects—including new tooling, sensors, and software—related to robotics.

10. NIST should work with industry to coordinate data collection and sharing to support AI and robotics. Unlike large language models, which train on a large corpus of publicly available Internet data or licensed digital media, AI use in robotics is constrained by a lack of data. There is limited data to teach robots how to move, grasp and manipulate objects, understand directions, and recognize activity in different environments, such as households, factories, and sidewalks. Computer scientist Hans Peter Brondmo has argued that it will take deploying “many thousands, maybe even millions of robots doing stuff in the real world” to collect enough data to train them to do more than generally well-defined, narrow tasks.[79] NIST should work with the robotics industry (including firms that use robotics) to identify barriers to greater data collection and sharing as well as solutions to these challenges.

Congress should increase funding for NIST’s Manufacturing USA program, including expanded funding for the ARM center.

Adoption

11. Charge NIST’s Manufacturing Extension Partnership (MEP) with creating a new robotics initiative that helps all centers better support SME manufacturers with adopting robots. As noted, few SME manufacturers use robotics. This is because the return on investment (ROI) does not meet hurdle rates, and also due to risk aversion and lack of both knowledge of robotics capabilities and expertise in implementation. Some state MEPs are exploring innovative ways to educate small manufacturers about the benefits of robotics. For instance, South Dakota MEP’s Automation Lab in Sioux Falls mitigates risk in acquiring new technologies by housing on-site cobots and providing a beta test environment for specific applications. South Dakota’s MEP operates a state-wide roadshow going into the field to demonstrate how rural manufacturers could effectively deploy cobots. The MEP program should develop a coherent strategy across states to educate U.S. small manufacturers on the benefits of robotics deployment and adoption.

12. Appropriate a modest amount of funds to NIST for a robotics best practices adoption award. Under this, SME companies could apply to use robotics in innovative ways, with NIST providing half the funding. As a condition of winning the award, a company would be required to share its learning with any other U.S. companies or organizations interested in learning about how the technology works and can be used. This is important because a major barrier for firms adopting robots is uncertainty about whether and for whom such an investment would pay off. Funding could be as little as $10 million per year.

13. The National Economic Council (NEC) should task each major agency with identifying application areas where robotics can assist in the completion of their missions. There is precedent for this. In the last decade, the Department of Interior was quite forward on the use of drones to accomplish its mission of managing federal lands.

That kind of approach should be used by all relevant agencies. For example, the Department of Interior could examine the role of robotics in forest and land management. The Department of Transportation could examine the role of robotics in road construction and maintenance. The Department of Health and Human Services could examine the role of robots in hospitals and other health care settings. The Department of Justice could support the deployment of policing robots.[80] Agencies such as the United States Postal Service and Federal Bureau of Investigation could utilize robotics in their missions, including warehouse operations. The Department of Homeland Security is an example of an agency that has received significant funds in the Big Beautiful Bill for deployment of technology to secure the borders, including from illegal drug traffic. Robotics could potentially play a role in drug interdiction at the border.

Because of its size and large procurement budget, the Department of Defense will likely play the largest role in purchasing robotics for the non-warfighter part of its mission. Unfortunately, there is no robotics coordinating function for all of the department. Purchasing and planning decisions are made in the services and at the decentralized levels within the services. While this should not change, Defense should have a dedicated assessment and coordinating role for departmental robotics use.

The National Institute of Standards and Technology should be charged with establishing an annual Robot Award with two categories: 1) the most innovative new robotics technology developed in the United States and 2) the most effective robotics application in the United States.

Federal agencies should also, where appropriate, work to support and encourage their state and local government counterparts to adopt robotics. For example, some states’ departments of Transportation use robots for bridge inspections. The U.S. Department of Transportation should identify and share these kinds of best practices with all state transportation departments. Other agencies should do the same, where relevant.

As part of this, NEC should issue a request for information from industry, soliciting cases where robotics could help achieve agency missions. Once these assessments are completed, each agency should be tasked with identifying how their own procurement could enable the increased adoption of robotics. It is important to note that this process should be a win-win wherein agencies adopt new technologies that help them perform their missions more effectively, ideally at a lower cost and with a lower head count, while also supporting U.S. robotics development.

14. The National Institute of Standards and Technology should be charged with establishing an annual Robot Award with two categories: 1) the most innovative new robotics technology developed in the United States and 2) the most effective robotics application in the United States. This is similar to what Japan has done with its annual “Robot Award.” The award would serve two purposes: 1) send a signal to American society that robots and robotization is something to be welcomed, not feared, and 2) provide an incentive for companies to innovate in the development and adoption of robotics, as gaining recognition from such an award would likely boost the health of these companies. Improved recognition could encourage additional R&D in robotics and boost adoption. And it would send a clear signal that the nation prioritizes, rather than fears and demonizes, robotics.

15. Refocus Small Business Association (SBA) loans and programs to help more U.S. manufacturers finance new production technologies. Due to intense working capital constraints, many small manufacturers are unable to make the up-front investments in robotics technologies that could have positive ROI paybacks in as little as two years. But SBA provides little support. In fact, according to one listing, of the top 40 industries in terms of 7A loan guarantees, all were local-serving companies and none were manufacturers that compete internationally.[81] That’s why the administration should urge SBA to focus its loan and loan guarantee programs more on U.S. manufacturers to help them finance new production technologies, including robotics.

Regulatory Issues

16. The National Institute for Occupational Safety and Health (NIOSH) should work with researchers, private companies, and government agencies responsible for setting workplace standards to modernize standards for robotics use in industrial and other settings. Current Occupational Safety and Health Administration (OSHA) standards limit facility managers and robotics companies from developing new robotics systems and integrating them into industrial settings.[82] NIOSH should develop new performance-based standards that enable companies to safely experiment with robotics systems. NIST should also be engaged in this process.[83]

Congress should boost the minimum wage and work to support President Trumps efforts to limit illegal immigration. When the price of labor is high, the ROI from investing in labor-saving technology is higher.

17. The White House should ensure that antitrust enforcers recognize the importance of scale in enabling a globally competitive robotics industry. For example, it was a major error by the Federal Trade Commission to reject Amazon’s proposed purchase of the U.S. firm iRobot.[84] Because the competitive position of iRobot was so weak, especially in light of aggressive, government-subsidized competition from Chinese competitors, the firm may now have to go out of business.[85] This is certainly not pro-consumer, and it is definitely not pro-America, as it means the Chinese will take over the consumer robotics business.

18. Congress should boost the minimum wage and work to support President Trump’s efforts to limit illegal immigration. When the price of labor is high, the ROI from investing in labor-saving technology is higher. Often referred to as the “Webb effect,” the theory is that a higher wage floor leads to higher levels of efficiency. Therefore, a reasonably set minimum wage indexed to inflation helps make it more economical for organizations to invest in robotics. The same is true with respect to low-wage immigration. Greater numbers of low-wage workers reduce capital intensity, as it becomes easier for employers to substitute workers for machines.[86] Congress has not raised the minimum wage since 2009. It should raise it to at least $12 an hour and index it to inflation.

19. As NEC works with agencies on robotics adoption, it should task them with assessing regulatory barriers in the areas of focus for each agency. For example, the Department of Housing and Urban Development could review how state and local building codes and other regulations inhibit the use of robotics in construction.

Workforce

20. NSF’s Advanced Technical Education (ATE) program should establish a center focused on technical training for robotics.[87] ATE is a top-notch program that supports the creation of leading-edge technical training institutes in emerging and foundational technologies. These institutes also help other technical and community colleges around the nation develop their own curriculums. ATE should fund at least one new center focused on robotics technician training for building, repairing, and using robots.

21. Support workers displaced by robotics. Congress should overhaul federal policies related to dislocated workers. ITIF has laid out a detailed, multipoint agenda for doing this.[88]

International Considerations

22. Limit Chinese robotics imports. As ITIF has documented, China is making rapid progress in the development and adoption of robotics.[89] The amount of government subsidies involved is truly astounding. And unlike those for R&D, they also include general subsidies that let Chinese robotics producers lower prices. While the PRC’s ability to dominate global markets in robotics is not as advanced as it is in other industries, such as solar panels, drones, and electric vehicles, it is rapidly increasing. In addition to subsidies, some Chinese robotics firms benefit from IP theft.

Moreover, the widespread adoption of Chinese robots also poses potential national security risks, as Chinese companies could be compelled to share data from, or allow remote access to, these robots. One path for a ban would be for the U.S. Department of Commerce’s Bureau of Industry and Security to develop a rule that restricts the import of robots and related hardware and software linked to China. Overall, the Trump administration should work to significantly limit, if not ban, Chinese robotics imports.

Chinese robotics producers are not competing on a level playing field. Many of the companies receive significant subsidies from Chinese governments.

Some will argue that America, including American manufacturers and other users of robots, benefit from cheap Chinese robotics. There are two problems with this logic. First, that is true for virtually all intermediate goods from China. At some point, the U.S. government needs to decide whether to go with short-term consumer welfare benefits or long-term U.S. competitiveness, especially for strategic industries, including robotics.

Second, it would be one thing if Chinese robotics producers were competing on a level playing field. But as ITIF showed in our Chinese robotics report, they are not.[90] Many of the companies receive significant subsidies from Chinese governments. There are also purchasing preferences for Chinese robotics enforced by the Chinese Communist Party (CCP). And in some cases, Chinese firms have relied on stolen IP. A letter from the Select Committee on the Chinese Communist Party to the Secretary of Defense states that leading Chinese robotics maker Unitree:

has participated in military-civil fusion programs, received PRC state funding… Unitree’s CEO Xingxing Wang appeared in a February 2025 closed-door CCP meeting with General Secretary Xi Jinping, seated in a top-ranking position. The firm is heavily subsidized as one of Hangzhou’s “six little dragons,” while also being backed by the city’s $140 billion Sci-Tech Fund and benefiting from its rapidly growing $21 billion robotics sector. It operates from the Hangzhou High-Tech Zone—a designated military-civil fusion hub—and has received multiple rounds of government support, including critical emergency funding that “br[ought] it back to life” when facing collapse.[91]

As such, it’s time for the U.S. government to take a stand against the import of unfairly produced Chinese strategic industry goods and services. It can start with robotics import bans.

23. Work with other nations on joint robotics research initiatives. The United States has strengths in certain areas of robotics, but other nations, especially Japan, South Korea, Germany, and Switzerland, are stronger. As such, federal agencies involved in robotics R&D should work to establish partnerships with any of these countries willing to engage in reciprocal efforts.

Conclusion

Robotics promises to be one of the most important technologies for the next quarter century. Robust innovation and widespread adoption across many sectors of the economy will be critical for future prosperity as well as national power. While, eventually, most organizations will adopt robotics as the technologies improve, that process can take a very long time—and in the meantime, U.S. productivity and living standards will grow more slowly than otherwise would be the case. While not having a national robotics strategy and policy would mean slower robotics adoption it almost assuredly would mean limited, at best, U.S. robotics industry capabilities. That would be extremely detrimental to U.S. power, as robotics is a key dual-use industry, not only in weapons but also as a way to cost-efficiently and quickly make weapons. Moreover, absent robust policy, China is almost surely going to lead in robotics, destroying in the crib (or at least in “elementary school”) the U.S. robotics industry, creating even more technology dependencies on China that will provide the PRC with even more leverage over America.

If the United States government wants to avoid losing in robotics to China, Congress will need to act big and bold as it did with semiconductors and the CHIPS Act. This would mean appropriating tens of billions of dollars for robotics adoption tax credits and robotics technology development. But even without that, there are a host of less-expensive policies detailed herein that should be adopted as soon as possible.

About the Authors

Dr. Robert D. Atkinson (@RobAtkinsonITIF) is the founder and president of ITIF. His books include Technology Fears and Scapegoats: 40 Myths About Privacy, Jobs, AI and Today’s Innovation Economy (Palgrave McMillian, 2024), Big Is Beautiful: Debunking the Myth of Small Business (MIT, 2018), Innovation Economics: The Race for Global Advantage (Yale, 2012), Supply-Side Follies: Why Conservative Economics Fails, Liberal Economics Falters, and Innovation Economics Is the Answer (Rowman Littlefield, 2007), and The Past and Future of America’s Economy: Long Waves of Innovation That Power Cycles of Growth (Edward Elgar, 2005). He holds a Ph.D. in city and regional planning from the University of North Carolina, Chapel Hill.

Meghan Ostertag is a research assistant for economic policy at ITIF. She was previously an intern with the Federal Deposit Insurance Corporation. She holds a bachelor’s degree in economics from American University.

Trelysa Long is a policy analyst at ITIF. She was previously an economic policy intern with the U.S. Chamber of Commerce. She earned her bachelor’s degree in economics and political science from the University of California, Irvine.

About ITIF

The Information Technology and Innovation Foundation (ITIF) is an independent 501(c)(3) nonprofit, nonpartisan research and educational institute that has been recognized repeatedly as the world’s leading think tank for science and technology policy. Its mission is to formulate, evaluate, and promote policy solutions that accelerate innovation and boost productivity to spur growth, opportunity, and progress. For more information, visit itif.org/about.

Update

This report was updated on August 11, 2025, to include additional examples of U.S. robot production.

Endnotes

[1]. Robert Atkinson, The Past and Future of America’s Economy: Long Waves of Innovation that Power Cycles of Growth (Washington D.C.: Edward Elgar Publishing, 2005).

[2]. Robert Atkinson, “Which Nations Really Lead in Industrial Robot Adoption” (ITIF, November 2018), https://www2.itif.org/2018-industrial-robot-adoption.pdf

[3]. “@Work Series: Employment in the Innovation Economy” (ITIF), https://itif.org/publications/2015/01/10/work-series-employment-innovation-economy/.

[4]. This is a key focus of robotics research in Japan; Thisanka Siripaka, “Japan’s Robot Revolution in Senior Care,” The Diplomat, June 1, 2018, https://thediplomat.com/2018/06/japans-robot-revolution-in-senior-care/.

[5]. Stephen Ezell et al., “Manufacturing Digitalization: Extent of Adoption and Recommendations for Increasing Penetration in Korea and the U.S.” (ITIF, August 2018), https://www2.itif.org/2018-korean-manufacturing-digitalization.pdf.

[6]. “My Dated Predictions,” Rodney Brooks, January 1, 2018, https://rodneybrookscom/my-dated-predictions/.

[7]. Joerg Mayer, “Robots and Industrialization: What Policies for Inclusive Growth?” (working paper, Group 24 and Friedrich-Ebert-Stiftung, New York, 2018), https://www.g24.org/wpcontent/uploads/2018/08/Mayer_-_Robots_and_industrialization.pdf.

[8]. Atkinson, “Which Nations Really Lead in Industrial Robot Adoption?”; International Federation of Robotics (IFR), “Global Robotics Race: Korea, Singapore and Germany in the Lead,” news release, January 10, 2024, https://ifr.org/ifr-press-releases/news/global-robotics-race-korea-singapore-and-germany-in-the-lead.

[9]. IFR, “Global Robotics Race: Korea, Singapore and Germany in the Lead.”

[10]. Ibid.

[11]. Ibid.

[12]. Ibid.; ILO Statistics, “Labor cost, Mean nominal hourly labour cost per employee by economic activity, 2015, 2022,” accessed February 16, 2024, https://ilostat.ilo.org/data/#; “International Comparisons of Hourly Compensation Costs in Manufacturing, 2016-Summary Tables,” The Conference Board, accessed February 14, 2023, https://www.conference-board.org/ilcprogram/index.cfm?id=38269; Statista, “Manufacturing labor costs per hour for China, Vietnam, Mexico from 2016 to 2020 (in U.S. dollars),” accessed February 20, 2024, https://www.statista.com/statistics/744071/manufacturing-labor-costs-per-hour-china-vietnam-mexico/.

[13]. IFR, “Global Robotics Race: Korea, Singapore and Germany in the Lead”; ILO Statistics, “Labor cost, Mean nominal hourly labour cost per employee by economic activity, 2015, 2022,” accessed February 16, 2024, https://ilostat.ilo.org/data/#; “International Comparisons of Hourly Compensation Costs in Manufacturing, 2016-Summary Tables,” The Conference Board, accessed February 14, 2023, https://www.conference-board.org/ilcprogram/index.cfm?id=38269; Statista, “Manufacturing labor costs per hour for China, Vietnam, Mexico from 2016 to 2020 (in U.S. dollars),” accessed February 20, 2024, https://www.statista.com/statistics/744071/manufacturing-labor-costs-per-hour-china-vietnam-mexico/.

[14]. Ibid.

[15]. Atkinson, “Which Nations Really Lead in Industrial Robot Adoption.”

[16]. Robert Atkinson, “Robotics and the Future of Production and Work” (ITIF, October 2019), https://itif.org/publications/2019/10/15/robotics-and-future-production-and-work/

[17]. Ibid.

[18]. National Science Foundation, Annual Business Survey (Table 80: Use of robotics as a production technology for goods and services, by industry: 2020–22, accessed July 15, 2025), https://ncses.nsf.gov/surveys/annual-business-survey/2023#general-notes.

[19]. Ibid.

[20]. Ibid.

[21]. Ibid.

[22]. Ibid.

[23]. Robotics 24/7 Staff, “World Robotics Report 2023 Shows Ongoing Global Growth in Installations, Find IFR,” Robotics 24/7, September 2023, https://www.robotics247.com/article/world_robotics _report_2023_shows_ongoing_global_growth_installations_finds_ifr; Daniel Workman, “Top Industrial Robots Exporters,” World’s Top Exports, September 2023, https://www.worldstopexports.com/top-industrial-robots-exporters/.

[24]. Robert Atkinson, “How Innovative Is China in the Robotics Industry” (ITIF, March 2024), https://itif.org/publications/2024/03/11/how-innovative-is-china-in-the-robotics-industry/

[25]. Ibid.

[26]. Ibid.

[27]. Anoosh Kumar, “Why The United States Needs Robots to Rebuild” (CSIS, July 2025), https://www.csis.org/blogs/strategic-technologies-blog/why-united-states-needs-robots-rebuild.

[28]. Atkinson, “How Innovative Is China in the Robotics Industry.”

[29]. Trade Data, UN Comtrade Database, https://comtradeplus.un.org/TradeFlow.

[30]. Kumar, “Why The United States Needs Robots to Rebuild.”

[31]. Observatory of Economic Complexity, Industrial robots in the United States (imports and exports of industrial robots in 2024), accessed July 15, 2025, https://oec.world/en/profile/bilateral-product/industrial-robots/reporter/usa

[32]. Ibid.

[33]. Ibid.

[34]. UR MiR | Teradyne Robotics, https://www.teradyne.com/robotics/.

[35]. Remarks of CEO Greg Smith, Q2 2025 Teradyne Inc. Earnings Conference Call, https://ir-api.eqs.com/media/document/cf3165e7-6e30-44c4-ac17-eb255b9e4e9c/assets/Teradyne_2Q25_Earnings_Call_Prepared_Remarks.pdf?disposition=inline.

[36]. Brent Donaldson and Peter Zelinski, “Made in the USA - Season 2 Episode 3: The Robots Come Home,” Modern Machine Shop, February 21, 2023, https://www.mmsonline.com/podcast/episode/made-in-the-usa---season-2-episode-3-the-robots-come-home.

[37]. Atkinson, “How Innovative Is China in the Robotics Industry.”

[38]. The Headquarters for Japan’s Economic Revitalization. New Robot Strategy: Japan’s Robot Strategy- Vision, Strategy, Action Plan (Tokyo, October 2015). https://www.kantei.go.jp/jp/singi/keizaisaisei/pdf/robot_honbun_150210EN.pdf; Kim Sang-mo, “Policy Directions for S. Korea’s Robot Industry,” Business Korea, August 17, 2018, http://www.businesskorea.co.kr/news/articleView.html?idxno=24394.

[39]. “Robotics” EU Business in Japan, August 2024, https://www.eu-japan.eu/eubusinessinjapan/sectors/electronics/robotics.

[40]. Internation Federal of Robotics, “Robotics Research: How Asia, Europe and America Invest,” news release, February 11, 2025, https://ifr.org/ifr-press-releases/news/robotics-research-goverment-programs-asia-europe-and-america-2025.

[41]. Park Sangsoo, “All Eyes on K-Robots: The Status and Strategy of Korea’s Robotics Industry”Invest Korea, May 9, 2025, https://www.investkorea.org/ik-en/bbs/i-5025/detail.do?ntt_sn=490807.

[42]. Internation Federal of Robotics, “Robotics Research: How Asia, Europe and America Invest.”

[43]. International Federation of Robotics, “World Robotics R&D Programs,” January 2025, https://ifr.org/downloads/hidden/20250117_World_Robotics_RD_Programs_V04.pdf.

[44]. Internation Federal of Robotics, “Robotics Research: How Asia, Europe and America Invest.”

[45]. Qinqie He, “Robotics Policies in Europe,” Equal Ocean, March 2, 2023, https://equalocean.com/analysis/2023030219515.

[46]. “Overview,” National Robotics Program, accessed July 14, 2025, https://astar-nrp-prod.netlify.app/research/.

[47]. “National Strategy for Robotics (NSR),” Insights IAS, September 13, 2023, https://www.insightsonindia.com/2023/09/13/national-strategy-for-robotics-nsr/.

[48]. Australian Government, Department of Industry, Science, and Resources, “National Robotics Strategy” 2024, https://www.industry.gov.au/sites/default/files/2024-05/national-robotics-strategy.pdf.

[49]. Joshua Bateman, “Why China is Spending Billions to develop an Army of Robots to Turbocharge it Economy,” CNBC, June 28, 2018, https://www.cnbc.com/2018/06/22/chinas-developing-an-army-of-robots-to-reboot-its-economy.html; Lilian Zhang, “China unveils new plan for wider robot use from manufacturing to agriculture, as population shrinks,” South China Morning Post, January 2023, https://www.scmp.com/tech/policy/article/3207622/china-unveils-new-plan-wider-robot-use-manufacturing-agriculture-population-shrinks?utm_source=rss_feed.

[50]. Paulina Szyzdek, “‘Made in China’-Robotics Market Overview,” Medium, September 29, 2024, https://medium.com/@paulinaannaszyzdek/made-in-china-robotics-market-overview-e0db03f640c5.

[51]. Atkinson, “Robotics and the Future of Production and Work.”

[52]. “Robotics Industry in Germany,” Germany Trade & Invest, accessed July 15, 2025, https://www.gtai.de/en/invest/industries/industrial-production/robotics-industry.

[53]. “Germany,” PWC | Worldwide Tax Summaries, June 29, 2025, https://taxsummaries.pwc.com/germany/corporate/tax-credits-and-incentives.

[54]. He, “Robotics Policies in Europe,”

[55]. Australian Government, Business, “Offset Your R&D Costs to Help Innovate and Grow Your Business,” accessed July 15, 2025, https://business.gov.au/grants-and-programs/research-and-development-tax-incentive/overview-of-rd-tax-incentive.

[56]. Minister for Industry and Science, “Grants Now Open to support a Future Made in Australia,” news release, May 2, 2024, https://www.minister.industry.gov.au/ministers/husic/media-releases/grants-now-open-support-future-made-australia.

[57]. “Shenzhen Introduces $630m Policy to Boost AI, Robotics,” Tech in Asia, February 24, 2025, https://www.techinasia.com/news/shenzhen-introduces-630m-policy-boost-ai-robotics; Brianna Wessling, “Beijing Announces $1.4B Robotics Fund,” The Robot Report, August 18, 2023, https://www.therobotreport.com/beijing-announces-1-4b-robotics-fund/.

[58]. Atkinson, “How Innovative Is China in the Robotics Industry.”

[59]. Government of India, Ministry of Electronics & Information Technology (METI), “Draft National Strategy on Robotics” (New Delhi: METI, 2024), https://www.meity.gov.in/static/uploads/2024/02/Draft-National-Strategy-Robotics.pdf.

[60]. “Our Work,” Dubai Future Foundation, accessed July 15, 2025, https://www.dubaifuture.ae/initiatives/future-design-and-acceleration/dubai-future-labs/our-work.

[61]. Ibid.

[62]. Atkinson, “How Innovative Is China in the Robotics Industry?”

[63]. “Germany’s Hub for Robotics and IA Excellence,” Robotics Institute Germany, accessed July 15, 2025, https://robotics-institute-germany.de/about-us/; Sebastien Lechevalier, Yukio Ikeda, and Junichi Nishimura, “The Effect of Participation in Government Consortia on the R&D Productivity of Firms: A Case Study of Robot Technology in Japan” (Institute of Economic Research Hitotsubashi University, Discussion paper series A No. 500, 2008), https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3146975.

[64]. “Robotics in Saudi Arabia: Leading the Tech Revolution,” Proven Robotics, April 9, 2024, https://provenrobotics.ai/robotics-in-saudi-arabia/.

[65]. Bruno Zabeu, “Brazil: The Next Big Automation Powerhouse?” Universal Robots, June 30, 2023, https://www.universal-robots.com/blog/brazil-the-next-big-automation-powerhouse/.

[66]. “Robotics Industry in Germany,” Germany Trade & Invest, accessed July 15, 2025, https://www.gtai.de/en/invest/industries/industrial-production/robotics-industry; “Industrial Automation’s Connection to the Growth of Advanced Manufacturing in Mexico,” Association for Advancing Automation, June 25, 2025, https://www.automate.org/robotics/news/industrial-automations-connection-to-the-growth-of-advanced-manufacturing-in-mexico.

[67]. “Taxation and Investment Guides and Country Highlights,” Deloitte, accessed October 3, 2011, https://dits.deloitte.com/#TaxGuides.

[68]. Osmond Chia, “National Robotics Programme Receiving $60m To Help Spur Robot Adoption in Industry,” The Straits Times, April 18, 2024, https://www.straitstimes.com/singapore/national-robotics-programme-receives-60m-to-help-spur-robot-adoption-in-industry.

[69]. Kim Sigyun, “The Korea Robot Industry Promotion Agency is Another Public Organization Under…” Maeil Business Newspaper, June 10, 2024, https://www.mk.co.kr/en/business/11037532.

[70]. “South Korea’s ‘Robot Tax’” WARC, October 8, 2017, https://www.warc.com/newsandopinion/news/south-koreas-robot-tax/en-gb/39118.

[71]. Daisuke Adachi et al., “Robots on Sale: The Effect of Tax Policy on Robot Adoption and Employment,”The Research Institute of Economy, Trade and Industry (April 2024), https://www.rieti.go.jp/jp/publications/dp/24e047.pdf; https://itif.org/publications/2019/10/15/robotics-and-future-production-and-work/.

[72]. “The Rise of China’s Robotics Industry: Modernize or Perish,” Asian Robotics Review, 2025, https://asianroboticsreview.com/home729-html.

[73]. Robert Atkinson et al., “Worse than the Great Depression: What the Experts Are Missing About American Manufacturing Decline.” (Information Technology and Innovation Foundation. March 2012). https://itif.org/publications/2012/03/19/worse-great-depression-what-experts-are-missing-about-american-manufacturing.

[74]. “A New National Purpose: The UK’s Opportunity to Lead in Next-Wave Robotics” (Tony Blair Institute for Global Change, October 8, 2024), https://institute.global/insights/tech-and-digitalisation/a-new-national-purpose-the-uks-opportunity-to-lead-in-next-wave-robotics.

[75] “Frequently Asked Questions for the Annual Integrated Economic Survey (AIES),” U.S. Census Bureau, March 27, 2025, https://www.census.gov/programs-surveys/aies/faq.html.

[76]. Robert D. Atkinson and Meghan Ostertag, “Congress Should Fully Fund NSF’s TIP Directorate to Make America More Competitive Versus China” (ITIF, June 2025), https://itif.org/publications/2025/06/30/congress-should-fully-fund-nsf-tip-directorate/.

[77]. “The Realization of Co-Robots Acting in Direct Support of Individuals and Groups,” National Science Foundation, https://www.nsf.gov/pubs/2016/nsf16517/nsf16517.htm.

[78]. U.S. Economic Development Administration, “Southwestern Pennsylvania New Economy Collaborative,” https://www.eda.gov/funding/programs/american-rescue-plan/build-back-better/finalists/southwestern-pennsylvania-new-economy-collaborative.

[79]. Hans Peter Brondmo, “Inside Google’s 7-Year Mission to Give AI a Robot Body,” Wired, September 18, 2024, https://www.wired.com/story/inside-google-mission-to-give-ai-robot-body/.

[80]. NYU School of Law, “Police Robots: Policy Framework” (NYU Policing Project), https://share.google/efXWrvZoOXGCbaqCy

[81]. Tami McMoran, “The Top 40 Industries for SBA Financing in 2020,” Capital Bank, June 1, 2020, https://www.westtownbank.com/resources/articles/top-industries-for-sba-financing/.

[82]. For example, OSHA standards for the control of hazardous energy (lockout/tagout) and machine guarding prevent many companies from fully integrating newer robot systems into their workflows, as companies must meet certain requirements designed for outdated technologies. In May 2019, OSHA issued a Request for Information in regard to updating lockout/tagout standards to better accommodate innovation in the robotics industry; however, the agency has not yet initiated a rulemaking process. NIOSH and OSHA should work with private organizations that design industrial mobile robots, warehousing and logistics companies that could implement robotics systems, academia, and other government agencies to revise these standards and enable companies to better integrate robots into their workplaces. Further, in order to account for future innovation, the agencies should focus on performance-based standards instead of design standards. Performance-based standards that protect worker safety would enable companies to safely pursue innovation without requiring that new robots meet the same design requirements as their predecessors.; Morgan Stevens, “Why Policymakers Should Support Robotic Automation to Solve the Productivity Crunch in Logistics Facilities” (ITIF, June 2023), https://itif.org/publications/2023/06/26/policymakers-should-support-robotic-automation-to-solve-productivity-crunch-in-logistics/.

[83]. Stevens, “Why Policymakers Should Support Robotic Automation to Solve the Productivity Crunch in Logistics Facilities.”

[84]. “Statement Regarding the Termination of Amazon’s Proposed Acquisition of iRobot,” Federal Trade Commission, January 31, 2024, https://www.ftc.gov/news-events/news/press-releases/2024/01/statement-regarding-termination-amazons-proposed-acquisition-irobot.

[85]. Irina Ivanova, “Roomba creator iRobot was once courted by Amazon for a vacuum revolution. Now, it might go out of business,” Fortune, March 13, 2025, https://fortune.com/2025/03/13/roomba-creator-irobot-amazon-going-concern-business-review/.

[86]. For example, Napasintuwong and Emerson estimate that limits on low-wage immigration to the United States would stimulate the adoption of additional available labor-saving technology with an increased substitution of capital for labor.; Orachos Napasintuwong and Robert Emerson, “Induced Innovation and Foreign Workers in U.S. Agriculture” (Selected Paper for presentation at the American Agricultural Economics Association Annual Meetings, Long Beach, California, July 28-31, 2002), https://ageconsearch.umn.edu/record/19738/files/sp02na03.pdf.

[87]. “ATE centers and Projects,” https://atecentral.net/centers/.

[88]. Robert D. Atkinson, “How to Reform Worker-Training and Adjustment Policies for an Era of Technological Change” (ITIF, February 2018), https://itif.org/publications/2018/02/20/technological-innovation-employment-and-workforce-adjustment-policies/.

[89]. Atkinson, “How Innovative Is China in the Robotics Industry?”

[90]. Ibid.

[91]. United States Congress Select Committee on the Chinese Communist Party, Letter to Secretary Hegseth, Secretary Lutnick, and Chairman Carr, May 6, 2025, https://selectcommitteeontheccp.house.gov/sites/evo-subsites/selectcommitteeontheccp.house.gov/files/evo-media-document/Unitree.pdf.

Editors’ Recommendations

February 28, 2005

The Past and Future of America’s Economy: Long Waves of Innovation that Drive Cycles of Growth

March 11, 2024

How Innovative Is China in the Robotics Industry?

November 19, 2018

Which Nations Really Lead in Industrial Robot Adoption?

January 10, 2015

@Work Series: Employment in the Innovation Economy

August 13, 2018

Manufacturing Digitalization: Extent of Adoption and Recommendations for Increasing Penetration in Korea and the U.S.

October 15, 2019